Jet bridge (also known as Passenger Loading Bridge, Passenger Boarding Bridge, Aviobridge or Jetty) is one of the most important pieces of equipment on an aircraft stand with regards to ramp safety.

It is the heaviest Ground Support Equipment (GSE) in the form of a large moving structure controlled by a single person. Due to its large size, weight and momentum, any collision between aircraft and the jet bridge is likely to cause more damage than most of the other equipment.

Moreover, being the largest piece of equipment on the ramp, the risk of collision does not lie only between the jet bridge and the aircraft but also between jet bridge and other Ground Support Equipment (GSE) working on the ramp.

Due to these reasons, there are considerably greater number of ramp safety aspects in the operation of jet bridges than there are with most of the other ground support operations. This is what today’s article is dedicated to.

Human Factors in Jet Bridge Operation for Ramp Safety

Once the preflight inspection is completed and aircraft is docked safely on the ramp (aircraft stand), jet bridge is operated by a human operator and engaged with the aircraft door to finally make that bridge connection for which jet bridge is given its name.

Human factors in jet bridge operation have special importance as compared to operation of any other ground support equipment (GSE) because a large moving structure is being controlled by a single person and is to be engaged physically with the aircraft body.

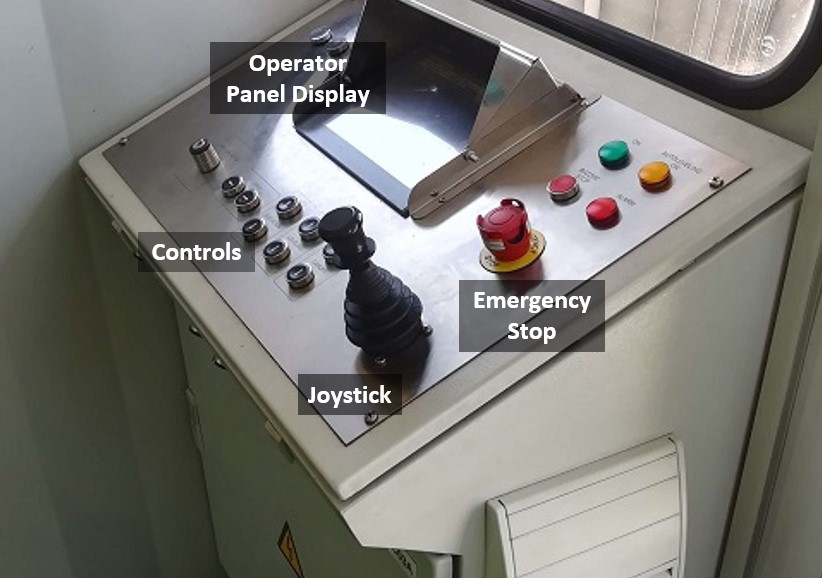

Jet bridge operation requires focus and alertness from the operator. The jet bridge is controlled from its cabin by a single operator who cannot visually see how the boundaries, edges and extremities of the jet bridge are moving on the ramp.

The operator does have some visual aids such as cameras installed in one or two strategic positions of the jet bridge whose feed is displayed on the control panel for the operator to observe while moving the bridge. However, it does not and cannot cover the entire bridge.

Due to the above reasons, jet bridge operation becomes a sensitive job. The operator relies on his (or her) feel to maneuver the jet bridge. This feel gets better with experience and includes having a good sense of what are the normal sounds and vibrations in jet bridge movement.

It becomes absolutely necessary that when the jet bridge operator is operating the bridge, there is no one inside of the jet bridge cabin other than the operator himself. No other staff of any agency is allowed to remain in jet bridge cabin when the bridge is being operated because it is a source of distraction for the operator.

Composure is another important trait needed in jet bridge operation. There are times when the jet bridge experiences some issue at the eleventh hour and causes delay in jet bridge engagement. Under such conditions, the jet bridge operator is under pressure to quickly connect the bridge because the flight is getting delayed. This pressure is dangerous because it negatively affects the focus and alertness required by the jet bridge operator and increases chances of error.

Work Fatigue is another important human factor to be considered in jet bridge operation. Since airports run 24/7, jet bridge operators work in shifts of night and day. For anyone who has worked in shifts it would be easy to understand that such a job is quite demanding on your body.

It is because your whole routine, especially your body sleep clock, must be organized around your job. For jet bridge operation, a job that demands attentiveness, alertness and focus at all times, it is important that consideration be given to the activeness of on-duty operators.

For the same reasons explained above, health, fitness and medical condition of jet bridge operators is also an important human factor. The sensitivity of jet bridge operation combined with the element of fatigue makes it necessary that people with certain health issues (such as diabetes, asthma and anxiety disorder) may not operate the jet bridge or operate with necessary aids.

Preflight Inspection of Jet Bridge for Ramp Safety

Preflight inspection of jet bridge is of paramount importance to make sure that the jet bridge is in normal condition before arrival of the aircraft. It starts from a complete walk-around of the jet bridge to notice if anything seems off like a broken glass or a hanging wire or maybe a dislodged sensor.

Apart from that, just like FOD check is carried out for safety of the aircraft, the same is also applicable for jet bridges. The jet bridge operator must check that there is no sharp object in the anticipated path of the jet bridge otherwise it can cause damage to the jet bridge tires.

Damage to the jet bridge tires is not only an expensive thing to deal with but also affects the safety of jet bridge movement because jet bridge tires not only provide a means to move the bridge but also help in balance and vibration control during jet bridge movement. It is so because jet bridges don’t have any shock absorbers or suspension systems like automobiles and rely on the cushion provided by their rubber tires.

Preventing Collision Between Jet Bridge & Approaching Aircraft on the Ramp

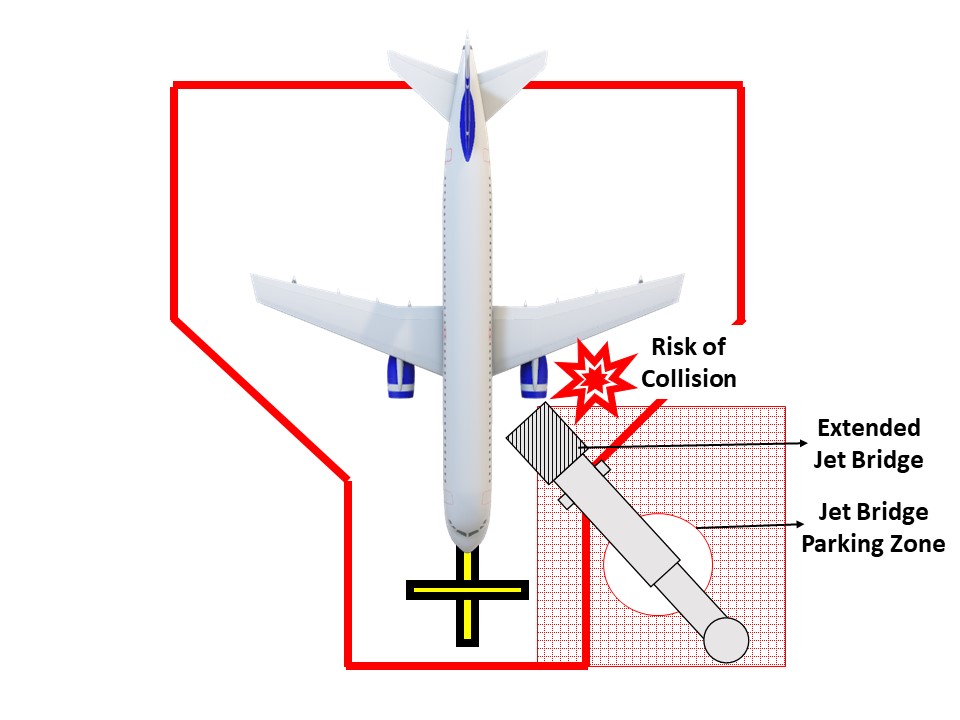

The next most important ramp safety aspect in jet bridge operation is that a jet bridge must remain in its home position (or parking zone) at the time of arrival of the aircraft. It has been discussed in detail in one of our earlier article on introducing ramp layout and ground markings.

However, briefly, jet bridges have a safety zone in which no other vehicle is supposed to be present especially during jet bridge movement. Within that safety zone, there is a ground marking (generally in the form of a shape) that indicates the parking position of the jet bridge by drawing the home position of jet bridge tires on ground.

Before arrival of the aircraft, tires of the jet bridge must remain over the marked zone and the jet bridge operator is not allowed by procedure to make movements while the aircraft is approaching the ramp. This is a critical safety measure because the ramp layout is designed to keep the bridges away from the aircraft when they are in their home position.

If the jet bridge operator has moved the bridge out of its home position, that safety is compromised and there is risk of collision between the extended jet bridge and the aircraft.

This particular aspect (of keeping the jet bridge in its home position) is also addressed by modern technology by electronic safety interlock between machines. The electronic safety interlock refers to communication between two machines with the ability of one machine to affect operation of the other machine under predefined conditions.

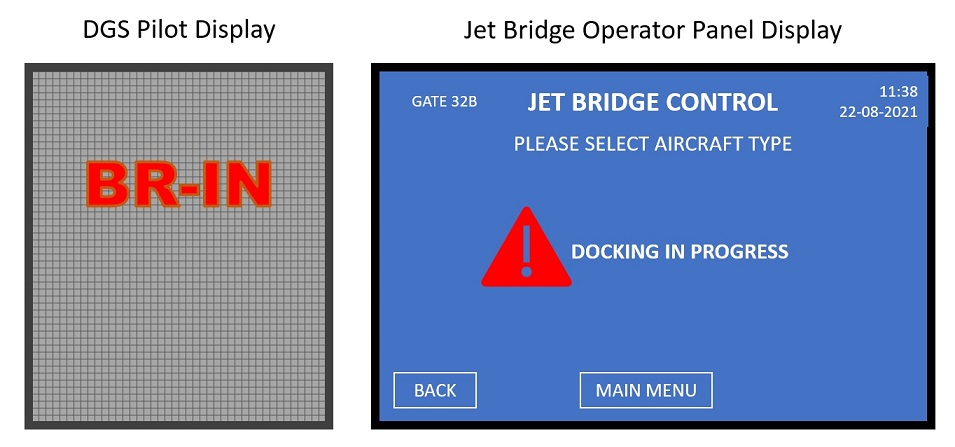

This safety of keeping the jet bridge in its home position at the time of arrival of the aircraft is built into the Docking Guidance System (DGS or VDGS) by many manufacturers. Jet bridge and docking guidance system (DGS) electronically communicate with each other such that the docking system informs the bridge if a docking is in progress and the bridge informs the docking system whether or not it is in its home position.

If the bridge is not in its home position and command for aircraft docking is given to the docking guidance system (DGS), the docking system will display a message such as “BR-IN” (represent Jet Bridge is potentially in the path of aircraft) on its display screen to alert the ramp staff that the docking procedure cannot be initiated until the jet bridge is returned to its home position.

Similarly, the interlock plays its role in preventing jet bridge movement while the aircraft docking is in progress. If the docking system is already busy docking an aircraft and the jet bridge operator tries to operate the jet bridge, it will not operate and will display a message on its interface to inform the jet bridge operator that a docking is in progress.

The electronic safety interlock ensure safety by locking equipment and eliminating chances of any incident due to human error during aircraft docking.

Safe Speed & Directional Control of Jet Bridge

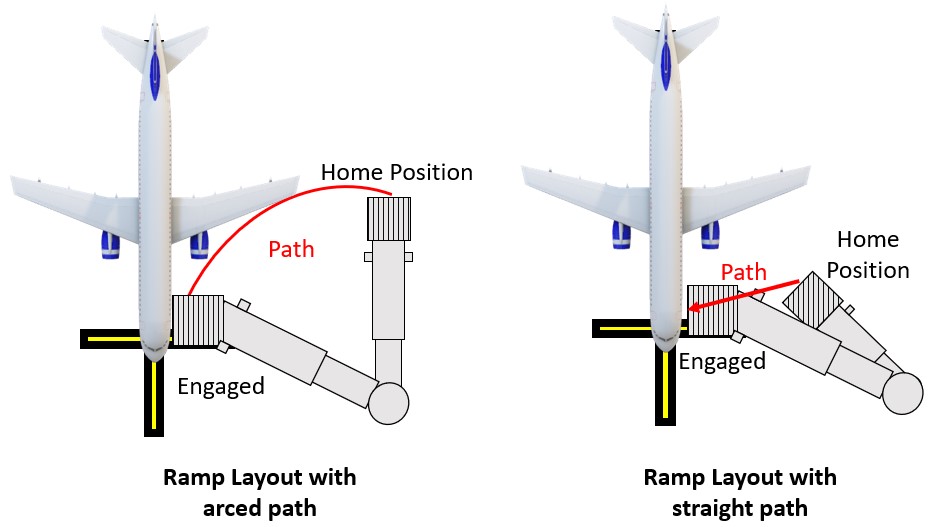

If the ramp layout is such that jet bridge engaged with the aircraft in roughly a straight-line path, it becomes a relatively easy operation. However, not all ramp layouts allow jet bridges to engage with the aircraft in a simple straight-line motion.

If the ramp layout is such that the jet bridge makes an arc when it engaged with the aircraft door, it is necessary that the jet bridge operator remains especially careful of the wing and engine of the aircraft. While this factor is taken care of during the design of ramp layout, it does not relieve jet bridge operator from the care needed to be exercised on his (or her) end.

The speed with which the jet bridge is operated is an important safety aspect. Generally, jet bridges have proportional controls i.e., the farther down the operator pushes the joystick on his console, the more speed the jet bridge will attain.

The safe speed of jet bridge operation is dependent on the direction of the bridge. The angle of wheels of jet bridge play important role in jet bridge’s stability during movement. When wheels of the jet bridge are parallel to the tunnels, overall bridge structure is in a more stable condition than when they are not parallel.

During straight extension and retraction movements, jet bridge wheels remain parallel with tunnels therefore bridge’s stability remains optimal. However, when the jet bridge needs to be rotated, its bogie wheels are turned to an angle to the tunnels and the stability of the bridge does not remain optimal. Under such movements, roll is induced in the jet bridge structure that is minimized by moving the bridge at its slowest speed.

As for the final part of engaging the jet bridge cabin with the aircraft door, it must always be performed with a reduced speed. Most modern jet bridges have electronic sensors that prevent the operator from moving the bridge too fast when the bridge sensors have detected that the aircraft is close to the bridge.

Preventing Collision of Jet Bridge with Other GSE on the Ramp

We have explained jet bridge safety zone and parking zone in one of our earlier articles. It is important that no vehicle or person is inside the jet bridge safety zone when the jet bridge is moving. All ramp staff as well as machinery including baggage loaders, cargo loaders, potable water truck and other ground support equipment must wait outside of the jet bridge safety zone until jet bridge operation is complete and jet bridge is engaged with the aircraft.

Technologically, there are safety features in all modern jet bridges to prevent a ramp accident involving jet bridge running into another piece of equipment or vehicle.

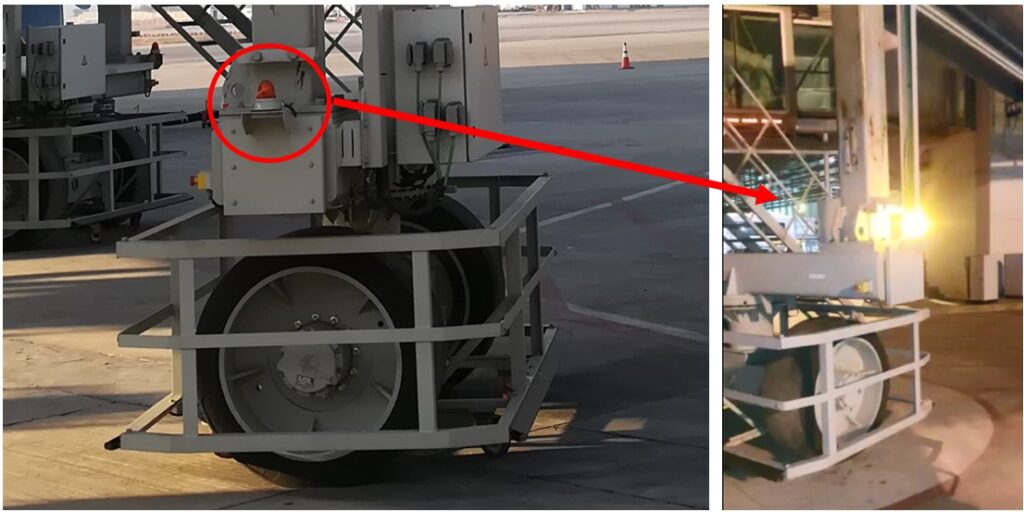

A loud audible siren is one of such features that keeps sounding throughout the movement of jet bridge to alert everyone on the ramp that a jet bridge is moving. Signaling flashing lamps are also installed on jet bridge wheel bogies for creating a visual signal during night time to alert ramp staff that jet bridge is moving.

It is also important to highlight the role of good maintenance practices in ramp safety. A sound maintenance program must be in place for jet bridges to conduct periodic inspection of all such safety features in order to maintain their reliability throughout the 20-25 year life of the jet bridge.

Jet Bridge Cabin Engagement – The Most Sensitive Part of the Job

The final part of the operation of jet bridge is most sensitive part from safety perspective. Jet bridge operator is supposed to either just touch the cabin bumper with the aircraft body or keep it hairline apart. This final part is where jet bridge operator’s skill is tested the most.

If the distance between cabin bumper and aircraft body is too much, there is risk of a passenger’s foot slipping through the gap resulting in injury. Conversely, if the jet bridge is not stopped at the right moment, the cabin bumper is hardly pressed with the aircraft body also giving the aircraft a push in the process. Correct and safe engagement of jet bridge with the aircraft requires precision in this final part of jet bridge operation.

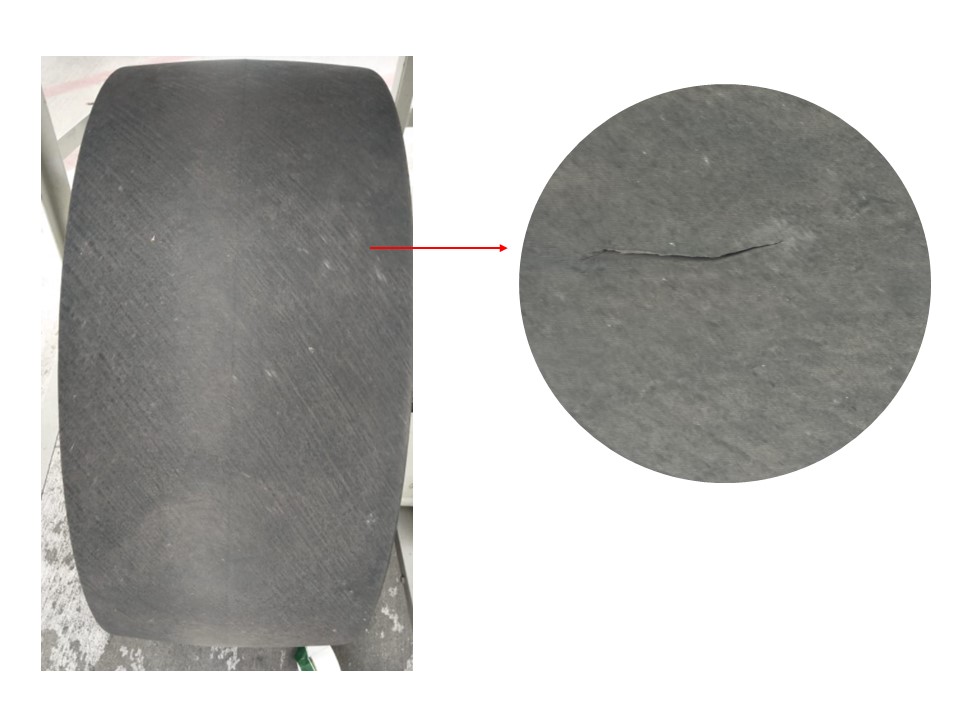

Another important safety aspect with respect to this final part of engagement of jet bridge with the aircraft is the proximity of aircraft sensors to jet bridge cabin. All aircrafts have different sensors over their body near the 1L door i.e., the front left door of the aircraft. These sensors include the angle of attack sensor and pitot tubes.

The position of these sensors is different in different aircrafts. In some aircrafts like Boeing 787 or Boeing 737, these sensors fall very close to the 1L door. This is where it becomes a safety concern in jet bridge operation due to risk of jet bridge cabin colliding with any of these sensors and damaging them.

Owing to the importance of these sensors in flight, it is a serious safety aspect and the concerned airport, airline or ground handling company must conduct a safety risk assessment for engagement of jet bridge on such aircraft types.

A possible risk mitigation can be a wingman who stands outside on the ramp when the jet bridge is being operated. He may guide the operator by communicating with him through a radio set for precise positioning of jet bridge cabin. He may also press the emergency stop of jet bridge if anything seems to be going out of control.

Finally, removal of jet bridge key from its console after completing engagement of jet bridge cabin the aircraft is a small but very important safety measure to prevent any unintentional command from being given to the jet bridge.

Technological Safety Features in Modern Jet Bridges

The latest innovations in jet bridge technology has introduced many advanced electronic safety systems to enhance ramp safety. We have a dedicated article to explain the engineering of jet bridge in detail including these modern safeties. However, we’ll briefly explain them here:

- Obstacle sensors on jet bridge wheel bogie to prevent ramp accidents involving collision between jet bridge wheel bogie with any object on the ramp.

- Passenger doors closure sensors to prevent someone falling from height from the jet bridge during its operation.

- Auto-leveling system and safety shoe sensor for preventing any ramp accident due to misalignment between jet bridge cabin height and aircraft door height.

- Automatic positioning or pre-positioning system for automating a significant part of jet bridge operating simplifying the job of operator.

- The dead man switch installed in jet bridge control joystick for preventing unintentional movements for safety.

- Electronic anti-collision systems in dual arm jet bridge setup to prevent collision between adjacent bridges during operation.

These safety features reduce chances of ramp accidents due to human error in jet bridge operation. They create an additional layer of safety such that for an accident to happen, it would require failure at two points, one at the technology level and second at human error level. However, reliability of these technological safety features depends on good maintenance practices.

Jet Bridge Training & Certification

Jet bridge stands among the most important ramp equipment and involves a lot of variables to be taken care of for ensuring safe operations. That is why it is important that jet bridge operators receive rigorous training and undergo certification and licensing before they are deployed in routine operations.

While the training always includes teaching the basic operation and controls of the jet bridge, it takes time for the operators to develop a feel for the jet bridge just like a person develops road sense when he learns to drive a car.

Only when the operator has reached the level when he feels confident and comfortable in jet bridge engagement with different aircraft types that arrive at the airport should he be given authorization for routine operations.

Generally, there is a certification or licensing system in place for jet bridge operators where the manufacturer of the jet bridge or specialized service providers impart training to operators in which the theoretical part may only take a week or two but the practice and getting-used-to part can take several weeks.

Training is generally not imparted from one operator to another. The general practice is to designate a master trainer who is authorized to impart training and assess if the operator is ready for operation.

Apart from the initial training, there are also refresher trainings and certification in place generally on annual basis.

It is important that the training curriculum and contents are also kept up to date and incorporate any changes in the equipment such as an upgradation of software. Plus it is very important that if any accident has takes place, its lessons learned are also included in operator training because it is very effective.

The training activity is kept properly documented and training records are auditable. In fact, in the event of any ramp accident, the investigation team is likely to check the training records.

s e p a r a t e

Keeping in view the sensitivity of jet bridge operation, the rules and regulations surrounding induction and training of operators are carefully developed in a heavily regulated aviation environment to pass safety audits and comply to international standards.

Case Study of Ramp Accident Involving Jet Bridge

On 12th December 2015, Ryanair flight FR6399 landed in Barcelona and docked on an aircraft stand where jet bridge was engaged. During disembarkation of passengers, as the weight of the aircraft reduced and height of its body increased, the auto leveler of jet bridge sent the signal to the bridge’s control system of the change in aircraft’s height.

The control system activated the elevation system that was hydraulic in nature, however, due to a fault in control system software as well as hydraulic valve responsible for lifting the telescopic columns, the bridge did not stop elevating even when it reached the level of aircraft door.

Consequently, the bridge’s elevation system kept raising bridge’s height until it gradually lifted the front landing gear of the aircraft off the ground. The aircraft door snapped, and the aircraft fell back on ground from a height of around 2 meters. No serious injuries were noted.

Detailed investigation revealed that the accident occurred due to malfunctioning of hydraulic valve combined with a shortcoming in jet bridge’s newly configured software system that did not stop the elevation system at the right time.

New software system was being installed as part of a jet bridge renovation program undertaken at the airport at that time and the software parameter that affected the auto leveling function was not included in testing protocols because such a failure was not anticipated.

This case study emphasizes the role of good maintenance and technical expertise in preventing ramp accidents.

So, this was all about ramp safety in jet bridges operation. If you liked this article, share it with at least one person of common interest. It allows our work to be of service.

If you are interested in obtaining a base level knowledge about ramp safety, check out this 7-hour video based course on Udemy that you can easily finish in a week (or binge watch in a day or two). It explains ramp safety in detail with interesting case studies of ramp accidents for in-depth understanding of the subject. It also explains ramp safety aspects associated with 13 main ground handling operations carried out on the ramp.