Airplanes take you from one corner of the world to another. Long haul flights are easily over 15 hours in which the airplanes carry hundreds of tonnes of payload in the air. To achieve this feat, airports have a fleet of refueling equipment and robust operating procedures in place for timely refueling hundreds of aircraft a day on busy airports.

In this article, we will explore the aircraft refueling process and the specialized equipment used for refueling.

Overview of Refueling Procedure

A wide body airplane like Boeing 777 has fuel storage capacity of over 150,000 tonnes. Airplanes are generally refueled before every long flight. Pilot checks after every flight, whether or not the existing fuel is enough for the next flight and makes the decision of refueling accordingly.

Once pilot has assessed the requirement of fuel, the amount of fuel to be added is given in units of weight (like kg or tonnes) to the concerned staff and it is the responsibility of ground handling crew and refueling staff to convert it into volume and fill accordingly. The requirement is recorded in what is commonly known as the Refuel Sheet.

The same sheet is handed over to the fueling company and fueling company’s personnel record the actual fuel uplifted (transferred from fuel source to the aircraft’s fuel tanks) by the fueling equipment. There can be slight differences in the requirement raised by the airline and the actual fuel uplifted therefore a refuel sheet records it.

Airport Fuel Farm

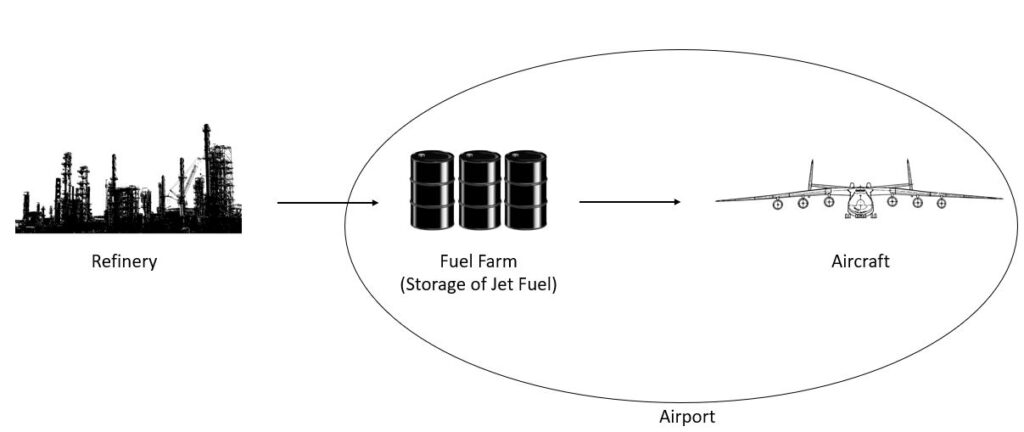

Airliners use kerosene based fuel in jet engines commonly known as Jet Fuel. At every airport, jet fuel is stored in a dedicated facility called a fuel farm. The concept is that oil refinery produces jet fuel, however, oil refineries are not always located close to the airports, therefore, it is not feasible to bring fuel from oil refinery to the airport frequently.

In order to deal with above problem, a dedicated facility for storage of fuel is created at every major airport in the world. It is called an Airport Fuel Farm. Jet fuel from oil refinery is delivered to fuel farm from time to time (based on fuel demand forecast for the respective airport) from where it is supplied to airlines for aircraft refueling either through a refuel trucking system or fuel hydrant system (both methods discussed below).

An airport fuel farm mainly consists of large storage tanks with allied systems for maintaining and controlling jet fuel quality. It is equipped with pumping system for fuel station or for underground fuel lines (in case of fuel hydrant system). It has metering systems for keeping track of quantity of fuel received and supplied. It has safety and fire protection systems to deal with hazards associated with fuel spillage. In short, an airport fuel farm is the main source of jet fuel at an airport.

Levels of Service in Aircraft Refueling

The levels of service in aircraft refueling refers to the guidelines defined by International Air Transport Association (IATA) in its “Standard Into-Plane Fueling Service Levels and Safety”, an extract from IATA guidance material on Fuelling Procedures.

IATA defines four levels of service in aircraft refueling where the first level is the minimum level for which a fuelling company must train its fuelling personnel while the fourth level is the most advanced level in which the personnel are trained to undertake non-routine fuelling procedures.

Level 1 is the Minimum Level of Service i.e. fueling personnel must be adequately trained to operate refueling equipment; know all of its functions and safeties and have sufficient training to approach the aircraft, identify the fueling port (ground service connection of the aircraft for engaging fueling equipment); physically connect the fueling nozzle with the aircraft fueling port and operate fueling equipment.

Level 2 is the Routine Fueling Service Level. At this level, in addition to fulfilling the basic requirements of Level 1, fuelling personnel must be able to receive and understand the total fuel figure from the airline; perform gauge and system tests for different aircraft types; make kg/lbs and litre/gallons conversions; use aircraft automatic loading settings to control the amount of fuel being added to the aircraft; understand how to communicate with cockpit via headphones on ground whenever required and understand the function of gauges installed on aircraft wing panel as well as aircraft fueling equipment to ensure normal operation.

Level 3 Service Level goes one step ahead and requires the fueling company to have personnel trained enough to check fuel distribution in the distributed fuel tanks of the aircraft and also have the competency to check fuel discrepancy in addition to all of the basic requirements of Level 1 and Level 2 service requirements.

The fueling personnel must be competent to obtain Refuel Sheet from the airline that is a document recording the existing fuel in aircraft fuel tanks, desired fuel quantity by the airline (generally decided by the Pilot himself) and the final fuel quantity actually filled. The personnel must be able to fill the sheet and communicate with the airline over it.

Moreover, the fueling personnel must also be able to calculate fueling discrepancy i.e. a difference of reading between the amount of fuel supplied by fueling equipment as measured by the fueling equipment gauge and the amount of fuel displayed by the aircraft’s fuel measurement system. Such discrepancies can arise in different scenarios including malfunctioning of fueling equipment gauges or the aircraft’s fuel measurement system therefore the fueling company’s personnel must be able to understand the situation when such a discrepancy arises and must also know the allowable tolerance.

Level 4 is the Non-Routine Fueling Service Level. At this level, fueling company’s personnel must be trained enough to conduct a manual fuel level check on the aircraft with the help of measuring sticks or magnasticks (or any other manual check instruments specified by the aircraft manufacturer). Such checks are needed when there is any uncertainty in the actual fuel levels in aircraft fuel tanks. Moreover, the personnel must also be able to carry out manual fueling (including overwing fueling – to be discussed in detail shortly) whenever needed such as in the event when refuel panel gauge or cockpit gauge is faulty.

In addition to above, fueling personnel must also be trained to perform transfer of fuel from one fuel tank to the other within the aircraft using the fuel pumps configuration installed in the aircraft itself. Defueling (emptying of fuel tank) procedure must also be known to the operator at this service level.

It is important to highlight that the service levels mentioned above are not mandatory for airports around the world. They are part of guidelines formulated by International Air Transport Association (IATA) and serves a reference material for airlines to follow to establish a training level and competency structure in fueling operations to ensure safety.

However, aircraft refueling operations will always be regulated by aviation authorities if not IATA and such regulations always mandate proper training of fueling company’s personnel that may not be exactly the same as IATA guidelines but will capture its spirit of ensuring competency in operators to handle different scenarios that can be experienced in aircraft refueling operation.

The Two Main Types of Refueling Infrastructures at Airports

There are two main types of refueling infrastructures at any airport,

- Refuel Trucking System

- Fuel Hydrant System

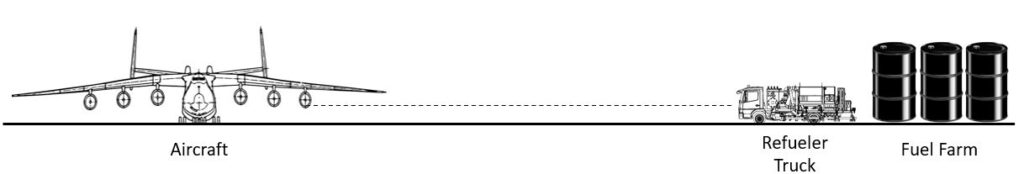

A Refueling Truck is simply a fuel tanker that carries several thousand liters of fuel in its tank and is fitted with necessary pumping systems to be hooked to an aircraft and top up its fuel. A fleet of Refueling Trucks is maintained at airports where this system is used and this fleet remains in action throughout the day refueling airplanes and replenishing themselves from the airport fuel farm once their tank is depleted.

A refueling truck is not much different from conventional fuel tankers. It is equipped with pumping system; fuel hoses for coupling with aircraft fuel receptacle; safety & protection devices for fuel hazards and metering device for measuring the volume of fuel transferred from the truck to the aircraft so that airline may be billed accordingly.

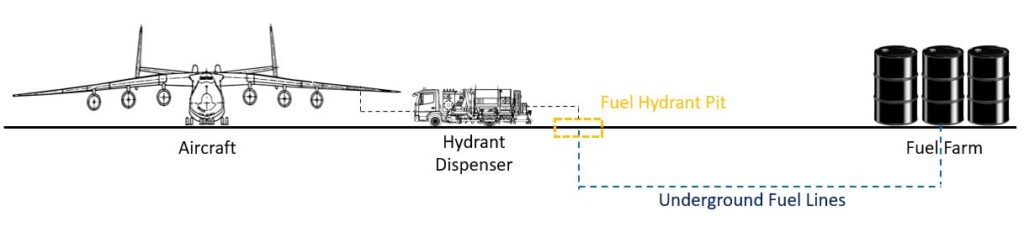

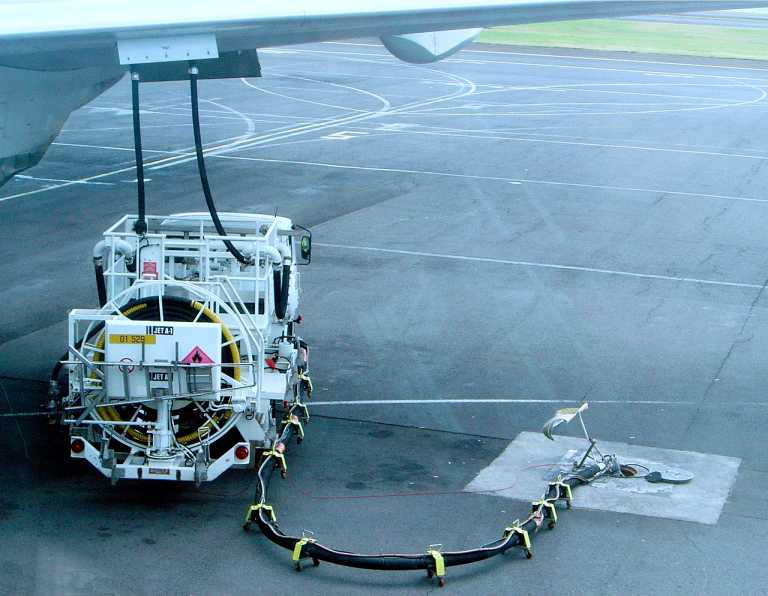

The other system is the Fuel Hydrant System. In this system, the airport is fitted with an underground network of fuel supply lines that reach from the airport fuel farm to aircraft stands/parking bays on airside. A Fuel Hydrant Dispenser is a specialized machine/vehicle that connects itself with the underground supply line on one end and the airplane on the other.

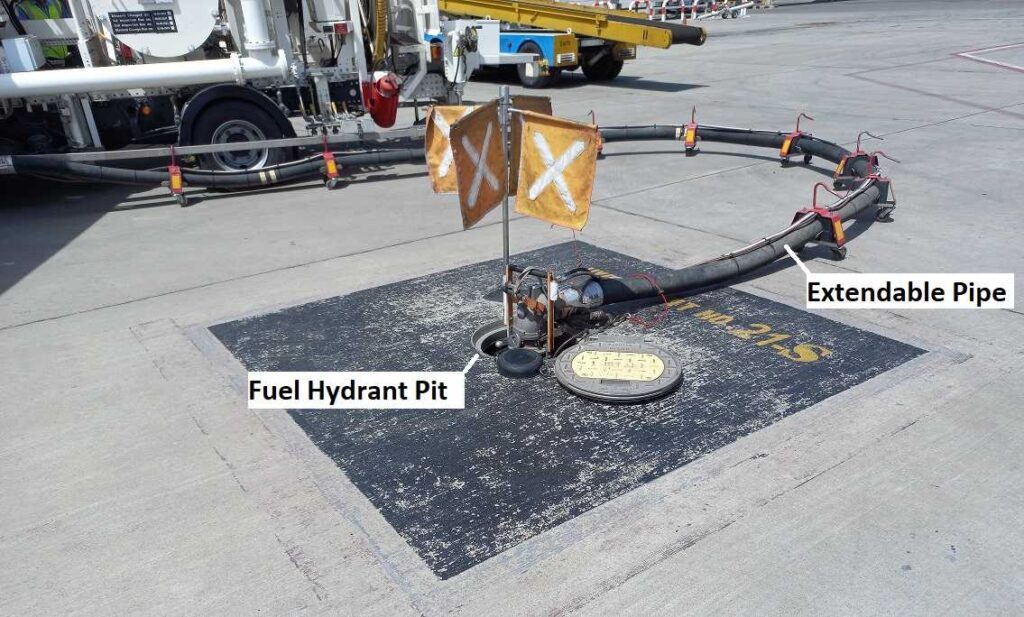

It is called fuel hydrant system because a fuel hydrant is installed on aircraft stand that is similar to fire hydrants installed on roads and streets. Just like fire hydrants are pressurized with water, fuel hydrant is a pressurized fuel supply point.

Fuel Hydrant Dispenser has ‘dispenser’ in its name because it neither carries any fuel nor has any pumping system for pulling fuel from the hydrant. It simply ‘dispenses’ fuel because fuel hydrant is itself pressurized enough for allowing fuel to make its way to the aircraft’s fuel receptacle located several feet above the ground.

Main Components of Fuel Hydrant Dispenser

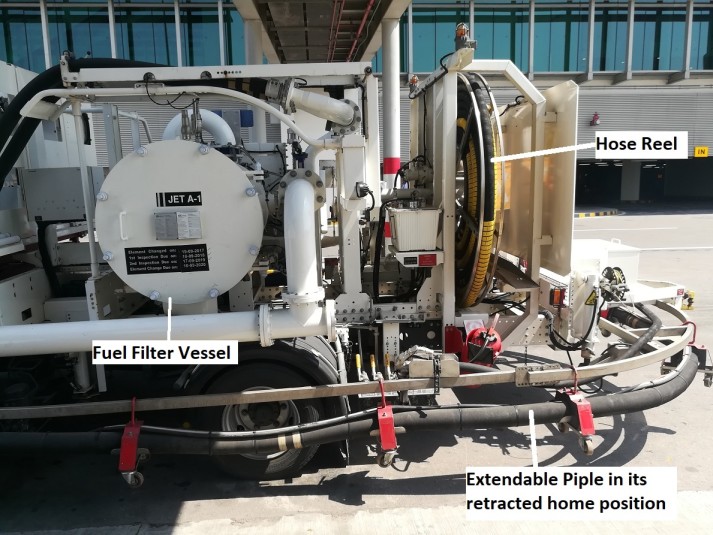

A fuel hydrant dispenser has the following main components,

1. Extendable Ground Pipe (for making connection with fuel hydrant pit)

2. Fuel Hoses (for making connection with aircraft fuel receptacle located in the wing of the aircraft)

3. Elevation Platform/Deck (to allow refueling staff to connect fuel hoses with aircraft fuel receptacle located several feet above the ground)

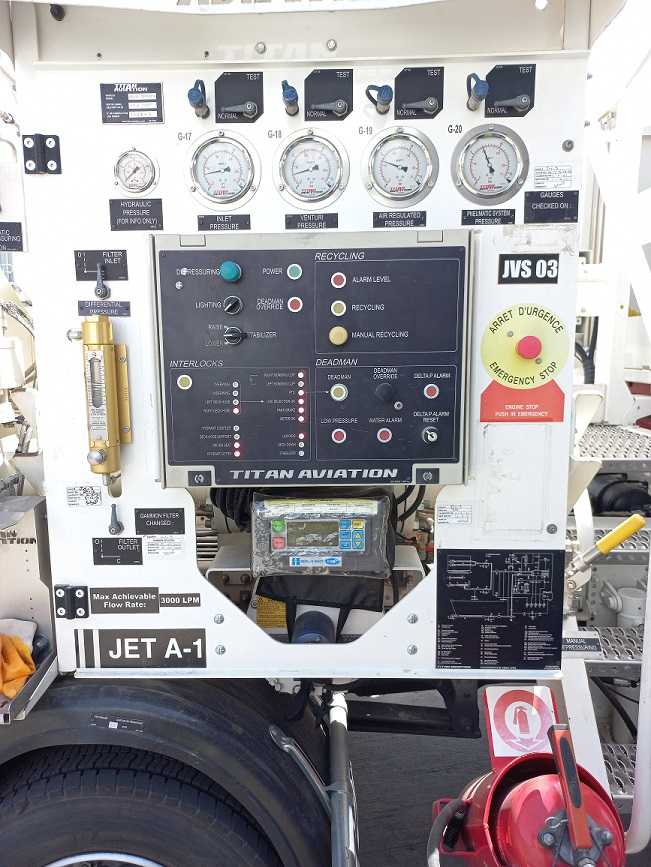

4. Fuel Filter (that filters the fuel to remove any impurity that has entered the fuel in the underground supply lines network)

5. Fuel Sampling System/Fuel Quality Inspection Apparatus (a special fuel quality test apparatus that allows the refueling staff to make sure no water content is present in the fuel)

6. Pressure gauges and metering device (that measure the fuel passing from the fuel hydrant pit to the aircraft)

All above systems are installed over a truck chassis for mobility.

Comparison of Aircraft Refueling Truck & Fuel Hydrant Dispenser

Both of the refueling infrastructures described above have their own pros and cons and all aspects are taken into consideration at the time of airport design and development to determine which infrastructure will best suite the airport. That being said, majority modern airports use fuel hydrant dispenser system for aircraft refueling. The reason will become evident by the end of this section.

1. Cost of Airport Design & Development

A refuel truck system bears lower cost of airport development as compared to hydrant dispenser system because the latter has added cost of civil and mechanical works for laying an underground fuel supply line network that extends from the fuel farm to airside of the airport reaching every aircraft stand.

2. Logistics & Transportation Expenses

Refuel Trucks have constant movement between airside and fuel farm because they have to replenish themselves from the airport fuel farm after servicing aircrafts. With hydrant dispenser system, the number of trips are reduced because the hydrant dispenser only has to move from its parking station to the required aircraft stand where refueling is to be carried out and where fuel hydrant pit is already present.

A fully loaded fuel tanker has a much higher fuel consumption when it is constantly moving a ton of fuel at its back. A fuel hydrant dispenser neither carries any fuel itself nor does it cover as much distance as a refuel truck therefore the transportation cost is reduced.

3. Safety Hazard

A refuel truck carries a higher safety risk because of possibility of accidents with other vehicles and ground support equipment that could result in fuel spillage. Since hydrant dispensers don’t carry any fuel, this risk is reduced.

4. Why Fuel Hydrant Dispenser is Preferred?

The choice between fuel hydrant dispensers and refuel trucks depends upon cost benefit analysis. If the added cost of development of an underground fuel supply network does not outweigh the benefits of using the simpler trucking system, it is not used.

However, majority modern airports use fuel hydrant dispenser system because its cost benefits with respect to easier logistics and transportation, and its safer mode of operation generally outweigh the cost saved by selecting fuel trucking system.

Overwing vs. Underwing Refueling

Now that we have fully explained the ground support equipment responsible for refueling an aircraft, let’s move on to explain two methods of refueling an aircraft. Airliners generally use underwing refueling that is simply refueling through the receptacle located under the wing of the aircraft.

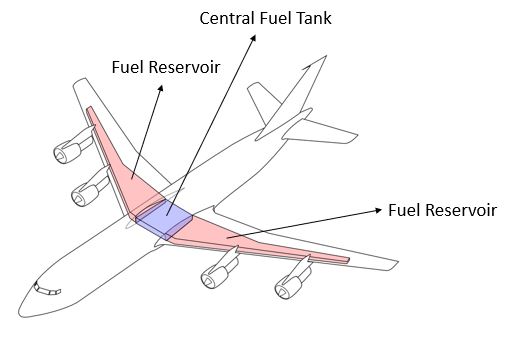

The wings of the aircraft are hollow from the inside and are used as fuel storage tanks. If you are surprised by this fact, let’s pause here and explain why aircraft wings are used for storing fuel? It has following main reasons,

- An aircraft wing is hollow from inside with a truss structure for structural support. The truss structure elements act as baffle plates to break liquid waves during aircraft maneuvers (analogous to design of water and oil tankers).

- Storing fuel in the wings of the aircraft also helps with maintaining a uniform center of gravity of the aircraft throughout the flight. If the fuel tanks were located towards the tail or nose of the aircraft, its center of gravity would shift by reduction weight of fuel due to ongoing fuel consumption.

- Moreover, fuel is consumed by aircraft jet engines that are installed on its wings. It provides simplicity in fuel supply design as fuel is available very near to the point of consumption.

Overwing refueling simply refers to refueling an aircraft through refueling receptacles located over aircraft wing. It is rarely used because overwing refueling is less automated than underwing refueling where amount of fuel being pumped into the aircraft is required to be monitored by the crew with the help of metering devices and gauges. Moreover, fuel transfer within different sections of fuel tank of the aircraft have to be manually controlled, whereas in underwing refueling, it is completely automated.

Apart from above, overwing refueling is also called gravity refueling because it operates on much lower pressure and flow rate than underwing refueling therefore it takes more time than underwing refueling to pump the same volume of fuel.

So this was it from our side. If you liked our post, do share it with likeminded people. It helps our efforts reach people who can benefit most from it.

If you are interested in obtaining a base level knowledge about all the different types of aircraft ground support equipment and operations, Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground support activities and equipment.