Did you know that narrowbody aircrafts like an Airbus A320 can carry more than 200 passengers while a jumbo aircraft like an Airbus A380 can carry more than 500 passengers on board. More passengers means greater use of airplane toilets!

Furthermore, narrowbody aircrafts like an Airbus A320 can fly nonstop for over 7 hours, for example between Bahrain and London Heathrow. On the other hand, widebody aircrafts like Boeing 777 and Airbus A380 can fly nonstop for over 17 hours on many long haul international routes. Longer flights means greater use of airplane toilets!

Apart from above necessity of having properly functioning airplane toilets, many widebody aircrafts have luxury washrooms for their business class passengers and a functional (at all times) aircraft lavatory system is part of the experience.

Today’s article is all about explaining aircraft lavatory system and how it is kept properly functioning at all times.

How do Airplane Toilets Work? – Aircraft Lavatory System Design

In view of all the factors described above that necessitate a fully functional aircraft lavatory system, all commercial aircrafts have a specialized system for handling waste.

Contrary to popular belief, aircrafts do not dump waste in the air. They collect all waste during flight in a specially designed waste tank.

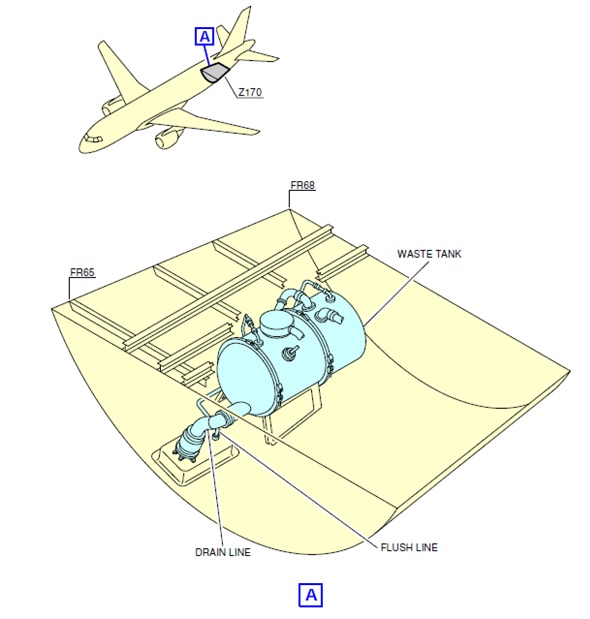

Picking the design of an Airbus A320 as an example, the airplane toilets are located towards the tail of the aircraft. All wastewater from the toilets is collected in a waste tank, which for a narrow body aircraft like an A320, can be of nearly 200 Liters capacity.

Flushing in an aircraft’s toilet is achieved through vacuum suction. This vacuum suction is achieved by pressure difference between the inside and outside of the aircraft. The toilet’s flush pipe that connects the toilet with aircraft’s waste tank is barometrically connected with the outside atmosphere.

At altitudes of above 15-16,000 feet, the atmospheric pressure outside the aircraft is lower than the pressure maintained inside the aircraft. Therefore, when you press the flush button of the toilet, all waste is sucked into the aircraft waste tank due to the pressure differential.

At altitudes below 15-16,000 feet when the natural pressure differential needed for creating the above stated suction is not available, a vacuum generator machine is available in the aircraft to create that suction mechanically.

The waste tank further has drain line and flush line of its own that are carried to the ground service connection port. It is located near the tail of the aircraft and is used by lavatory service equipment to connect and carry out lavatory servicing.

Aircraft Lavatory Service Procedure

As mentioned earlier that the waste storage tank of an aircraft has limited capacity, the waste tank needs to be drained to keep airplane toilets functioning properly on the next flight. If waste tank becomes full, the airplane toilets would stop working.

The procedure of lavatory servicing is aimed at simply emptying the waste tank of the aircraft after every flight (or when the waste tank becomes full).

Aircraft lavatory service procedure uses a specialized piece of equipment known as lavatory service truck to drain and flush aircraft waste tanks.

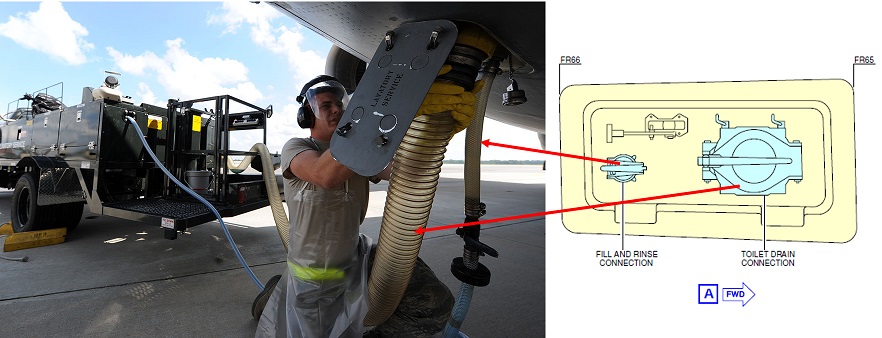

The lavatory service port of the aircraft has a drain line used for draining all the waste and a flush line that is used by lavatory service equipment to inject a disinfectant solution for rinsing the waste tank.

Aircraft lavatory service procedure has following main steps:

- The operator drives the lavatory service truck to the aircraft stand.

- He/She parks the truck with its back towards the aircraft because that is where the drain hose and flush line can conveniently connect with the aircraft lavatory servicing panel.

- He/She finally make the connection between the service truck’s waste tank and aircraft lavatory servicing panel.

- First, the drain valve is opened that results in all of the collected waste getting drained into the lavatory service truck’s waste tank.

- Secondly, the rinse connection may be used to clean and disinfect the waste tank with aircraft lavatory fluid which is a disinfectant fluid used to clean aircraft’s waste tank.

- The drain hose and rinsing hose are disconnected and secured back in lavatory service truck.

- Lavatory service truck is removed from the aircraft stand.

Safety in Aircraft Lavatory Servicing

In aircraft lavatory servicing, the operator must be provided proper Personal Protective Equipment (PPEs) to prevent any health related problems due to the possible exposure to germs and bacterial contamination associated with the job inherently.

The operator must be given a proper face shield, hand gloves and a suit that saves the operator’s skin from waste leakage (if any) or the flushing chemicals.

The operator must be careful in positioning of the aircraft lavatory service truck as the truck’s final positioning involves reversing the vehicle into positition. It is specially important for narrowbody aircrafts because their ground clearance may not be enough to let the truck get under the aircraft without colliding.

If needed, the lavatory service truck operator may use help of another ramp agent (as marshaller for the truck) to ensure safe and precise positioning of the truck near aircraft tail.

Proper vehicle exit procedure and care must also be observed when the operator leaves the truck to make connection of hoses with the aircraft.

After the lavatory service truck is properly positioned, chocks may be applied on its wheels and cones may be placed around the truck.

Parking brake and application of chocks is an important safety measure not to be forgotten. The last thing you’d want is the truck rolling away while operator is making the connection.

The lavatory service truck has a small operation time and it must leave the ramp as soon as their job is done. Unnecessary parking Ground Support Equipment (GSE) causes congestion on the ramp that increases risk of accident.

Last but not the least, both lavatory servicing and potable water servicing access panels are located at the rear side of the aircraft in the line of the aircraft jet blast zone. If due to any miscommunication or confusion, aircraft jet engine is started while the truck is still parked, it could tip the truck over and cause a serious accident.

Therefore, precaution must be exercised both from the side of flight crew as well as servicing personnel to prevent any incident.

Aircraft Lavatory Servicing Accident Case Study

On 02nd July 1999 at General Mitchell Airport in Wisconsin, United States, a DC-9 aircraft operated by Midwest Express Airlines was parked at an aircraft stand when a lavatory service truck reached to perform a routine lavatory servicing.

The driver was backing up the truck for parking with correct alignment with the aircraft. While backing up, she accidentally stepped on the accelerator pedal instead of the brake pedal due to slipping of her foot.

The truck accelerated in reverse and collided with the aircraft before she could apply the brake again. The collision caused substantial damage to aircraft body. The accident was investigated by National Transportation Safety Board (Ref. Accident No. CHI99FA208, Aviation Accident Final Report, National Transportation Safety Board of United States).

The operator told that she did not use assistance of a person as marshaller for parking of the truck because no one was working on that side of the aircraft. The accident emphasizes the importance of safety in positioning the truck near the aircraft.

Types of Aircraft Lavatory Service Equipment

There are two main types of a lavatory service equipment.

- Aircraft Lavatory service truck is the most common type where all equipment components are installed over a truck.

- The other type is Aircraft lavatory service cart in which all components are installed over a cart that is needed to be towed to the desired location by a towing tractor.

All large airports use lavatory service trucks because they can service more aircrafts than a lavatory service cart and they don’t require any external machine such as a towing tractor for their movement.

Aircraft Lavatory Service Truck Design

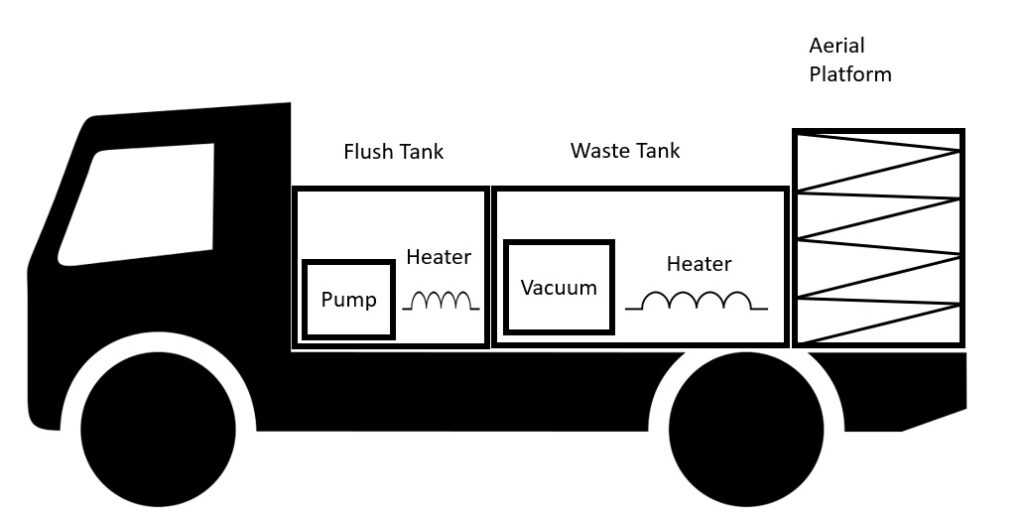

A lavatory service truck is a collection of components installed over a truck chassis. It has two main tanks. One is the waste tank that stores the waste drained from the aircraft. The other is the flush tank that stores the disinfectant liquid (often referred to as the blue water) used for rinsing the aircraft’s waste tank.

Flush tank is installed with a pump used for pumping the blue water into the aircraft’s waste tank for rinsing.

Lavatory service trucks can also be equipped with an aerial platform, that allows the operator to reach aircraft lavatory outlet because on larger aircrafts, the outlet is not reachable without any aid.

Some trucks also have a vacuum system installed with the waste tank that allows faster suction to reduce service time.

Some manufacturers also provide heaters in waste tank and flush tank to avoid the liquids from getting frozen in extremely cold weather on airports that experience sub-zero temperatures.

The Overall Aircraft Waste Disposal Process at Airports

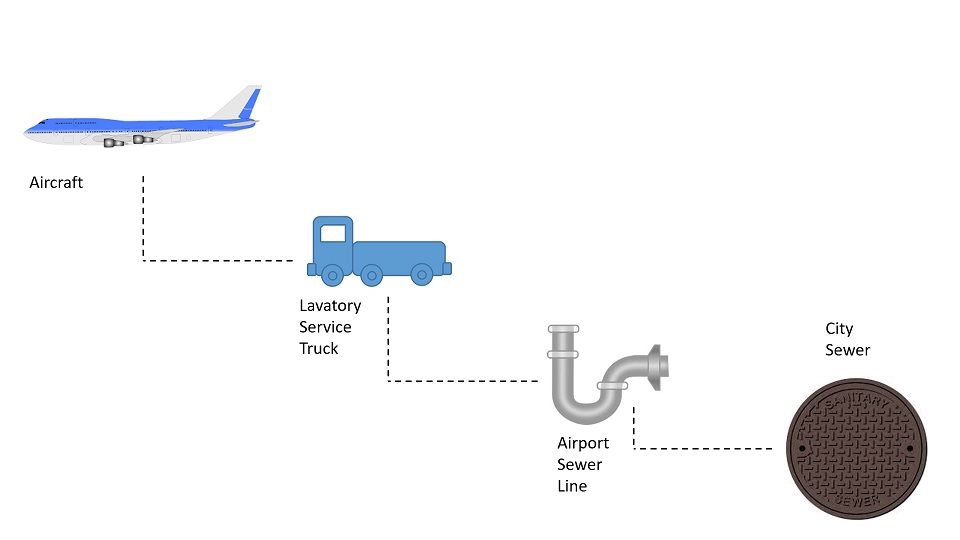

While the aircraft lavatory servicing is completed when the aircraft’s waste tank is emptied, the overall aircraft waste handling continues until proper disposal of aircraft waste.

When the aircraft lavatory service truck leaves the aircraft stand, it is taken to a dumping site at the airport where the truck empties itself so the next aircraft can be serviced.

The dumping site at the airport connects with the airport sewer line which in turn is connected to the city sewer system. In this way, waste from the aircraft is dumped into the city sewer.

Alternatively, the airport sewer system may be connected to a wastewater treatment plant at the airport for recycling wastewater for use in toilets and horticulture within the airport premises.

So this is it from our side. If you liked the information we have presented, please do share it with likeminded people so our efforts could reach where most benefit can be derived from them.

If you are interested in obtaining a base level knowledge about all the different types of aircraft ground support equipment and operations, Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground support activities and equipment.

Or, if you are interested in obtaining a base level knowledge about ramp safety, check out this 7-hour video based course on Udemy that you can easily finish in a week (or binge watch in a day or two). It explains ramp safety in detail with interesting case studies of ramp accidents for in-depth understanding of the subject. It also explains ramp safety aspects associated with 13 main ground handling operations carried out on the ramp.