As soon as passengers have settled in the airplane and the flight takes off, there is a lot of anticipation of on board meal. What is on the menu today? Is there gluten free meal available or not? Do they have vegetarian meal or not?

However, there are many intriguing questions for people interested in knowing how catering works. In this post, we will explore airline catering facilities and aircraft catering equipment to explain how the whole flight catering system works.

Scope of Aircraft Catering

In order to understand the importance of airline catering, please note that there can be more than 150 passengers on a small aircraft like Airbus A320. On a larger aircraft like Boeing 777, there can be more than 300 passengers on board.

An Airbus A380 can have more than 500 passengers on board. These airliners can easily have long haul flights of more than 15 hours flight time. An airline needs to provide meals and snacks to all passengers and crew remaining onboard for extended periods of time.

To further compound the situation, busy airports around the world have hundreds of flights per day and preparation, packaging and management of meals and catering supplies becomes a big challenge airlines.

Apart from the primary objective of serving in-flight meals, the same catering facility can be used for serving airport lounges and airline staff offices.

According to Business Insider April 2019 Report on Emirates Flight Kitchen in Dubai, it is the world’s largest catering facility that prepares around 225,000 flight meals a day and 110,000,000 flight meals a year. It receives 3,000,000 pieces of tableware a day for washing and packaging.

Emirates has 1,800 chefs working around the globe who develop more than 1,300 menus a month for different flight routes and destinations. Generally, menu of each flight is inspired by cuisines and culinary style of the arriving destination.

(Image Credit Wikimedia Commons/Australian Airlines)

Flight Kitchen (or Flight Catering Facility)

Meals served on the aircraft by the airline are not prepared on board. There is a facility dedicated for preparation of flight meals called Flight Kitchen that is located at the airport or its vicinity.

Flight kitchen is simply a large facility for mass preparation of flight meals. It has a team of chefs and catering staff working 24/7 in shifts preparing meals for their airline.

For example, the Emirates Catering Facility referred above is a multiple story facility with different sections assigned for different jobs such as dish washing, servicing of meal trolleys, preparation of appetizers, preparation of deserts and a separate cooking and meal preparation section for Asian, Subcontinent, European and Middle Eastern food respectively.

Large flight kitchens can have considerable automation involved including conveyor belts for controlling pace of meal packaging across different sections of a flight kitchen; automated plastic wrapping of meal packages; automated washing equipment for catering cutlery and accessories; automatic rail system for traveling of meal trolleys through different servicing sections.

Flight kitchens don’t give a kitchen vibe at all if you neglect the appetizing aroma of different meals being prepared. They rather give the impression of a factory or facility that is not cooking food but manufacturing it in a production line fashion.

Logistics is the backbone of Flight Catering process and Flight Catering Facilities have large fleets of Aircraft Catering Trucks that are basically height loaders of different specifications compatible with different aircraft types (we’ll discuss the design of aircraft catering truck in more detail shortly).

For example, the same Emirates Catering Facility in Dubai we discussed earlier has a transport fleet of 424 vehicles including 295 height-loader trucks and 89 specialized height-loader trucks to service the largest aircraft i.e. Airbus A380.

(Image Credit: Wikimedia Commons/SAS Scandinavian Airlines)

The importance of hygiene and safety in Flight Catering Facility is of paramount importance. Flight kitchens can have Food Analysis Laboratories on site to conduct different tests important for compliance with food standards.

Owing to the technology and automation involved, Flight Catering Facilities can have in-house maintenance workshops and team of engineers and technicians for maintenance of equipment.

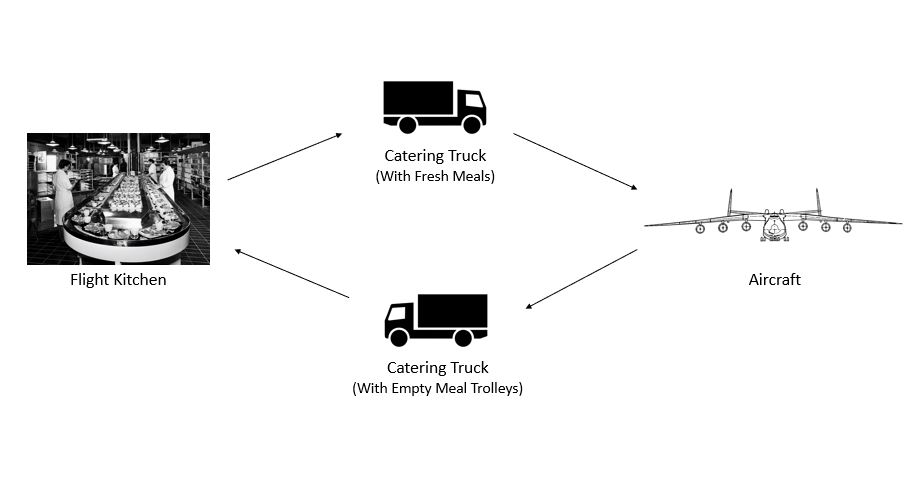

Flight Catering Process

The complete catering process of airlines consists of several main steps as given below,

1. Flight kitchen receives order of the meals to be served onboard for forthcoming flights. The order is based on a meal plan already prepared in advance for the different flights operating at any given day.

2. Kitchen staff checks the different meals requested on the menu and prepares a plan for preparing the meals in advance.

3. Kitchen staff cooks the meals and make portions of the meal ready to be served to passengers and crew.

4. This cooked food is generally not sent straight away to the airplane. It is first cooled down at a storage temperature.

5. The meals that are now in the form of packages are loaded on meal trolleys. Several fully loaded meal trolleys become ready to be transferred to the aircraft and are sent to flight kitchen loading bays.

6. The flight kitchen loading bay is a place like any other logistics facility loading area where a designated gate is assigned for parking a truck with its rear bumper aligned with the bay gate so that from the facility’s side, it appears as if things are being transferred from the facility to a room. All meal trolleys are loaded up into the Aircraft Catering Truck.

7. At this point, the meal trolleys leave the Flight Kitchen and the Aircraft Catering Truck travels to reach the aircraft stand where the respective aircraft is parked. There are several security checkpoints the truck goes through before it finally reaches the aircraft.

8. New meal trolleys cannot be loaded on the aircraft until the existing meal trolleys whose meal packages have been consumed on flight are removed. Therefore, at the time when Flight Kitchen is loading up the new truck, another truck that reaches the aircraft as soon as it arrives lines up with the aircraft so that crew could unload all of the existing meal trolleys from the aircraft onto the Aircraft Catering Truck.

9. It is the responsibility of Ramp Supervisor and airline crew to make sure that the unloading of old catering supplies and meal trolleys is finished by the time the freshly loaded Aircraft Catering Truck reaches the aircraft stand. It requires coordination between ground staff, crew onboard and flight kitchen.

10. Once all of the existing catering supplies (mainly used up meal trolleys) have been loaded up on the truck, it leaves allowing the freshly loaded truck to engage with the aircraft.

11. At this stage, airline crew gets busy transferring all of the meal trolleys from inside the truck to the aircraft. After all meal trolleys have been transferred into the aircraft, the catering truck is disengaged and removed from the aircraft. This same catering truck that brought freshly loaded meal trolleys remains on apron. It is used for unloading consumed meal trolleys from the next flight of the airline.

12. Meanwhile, the Aircraft Catering Truck that had picked the old meal trolleys returns to the Flight Kitchen where all meal trolleys are unloaded. All contents of the meal trolleys are emptied and washed including servicing of the meal trolleys themselves. Once fully serviced and cleaned, these meal trolleys with their cutlery and accessories are used for packing meals for future flights. Similarly, the truck that had brought the used up meal trolleys is sent to the apron fully loaded with freshly loaded meal trolleys for the next flight. In this way, a single truck is used both for carrying fresh supplies to the aircraft as well as retrieving consumed meal trolleys.

The fleet of Aircraft Catering Trucks keep moving back and forth between apron and flight kitchen to replenish flights catering supplies.

Engineering Design of Aircraft Catering Truck

The aircraft catering truck may appear like a simple truck from the outside, however, it is a sophisticated piece of equipment. Let us explain the technology of an aircraft catering truck.

(Source Image Credit: Wikimedia Commons/Renata3)

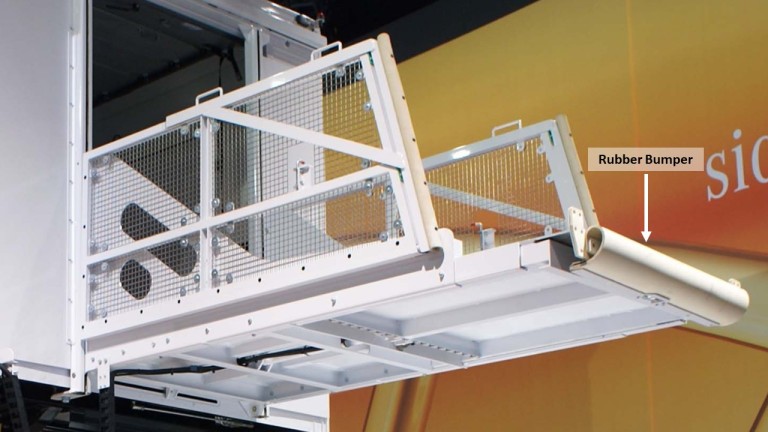

A catering truck stores meals in meal trolleys inside its container. It has a scissor lift elevation system to raise the container to the level of aircraft door and make a safe bridge connection through an adjustable platform to allow the staff to replace meal trolleys.

Catering truck has the tendency to topple under high speed winds because its weight is distributed in a way that makes it prone to swaying.

For that reason, catering trucks have built-in outriggers or stabilizers that are supports of catering truck to remove the load from the wheels of the truck and offer additional solid support and foundation on the ground to fight wind forces and other external forces that try to tip the truck over in elevated position.

The aircraft catering truck also has a rubber bumper in its extendable platform to make a soft connection with the aircraft and save the aircraft body from any damage during catering operation.

Catering supplies are replenished by replacing food trolleys and not just meal packages. Flight kitchen loads up meal packages in food trolleys that are loaded in the catering truck.

When catering truck is connected with the aircraft, airline staff loads the aircraft with fresh trolleys and empty trolleys are loaded back into the catering truck.

Catering crew must also not forget to extend the safety rails over the extendable platform. The extendable platform is a narrow bridge connection at a great height from where a person could fall during work causing a potentially fatal injury.

Therefore, the importance of safety rails cannot be over emphasized. It is critical for preventing a fatal accident in catering operation.

Aircraft Catering Truck Models & Configurations

Different aircraft catering trucks have different service heights, container sizes and payload rating based on the largest aircraft they are designed to service.

For example, an aircraft catering truck designed to service smaller aircraft like an Airbus A320 will have a smaller container size, payload capacity and service height than a catering truck designed for servicing an Airbus A380.

Aircraft catering truck manufacturers manufacture many different variants for airlines and ground handling agencies to select from based on the aircraft fleet they operate.

(Image Credit: Wikimedia Commons/Antoine FLEURY-GOBERT)

Apart from the models and configurations based on catering truck capacity and dimensions, some manufacturers are introducing catering trucks with state of the art automation technology.

A good example is the automated trolley movement system in catering truck containers by manufacturer ATL Systems. The container is fitted with an automated trolley conveying system that automatically brings new trolleys forward towards the aircraft door. It reduces loading and unloading time by eliminating the need of airline staff manually organizing food trolleys inside catering truck container.

Safety Features in Aircraft Catering Trucks – How Modern Technology Enhances Safety

Apart from the basic parts described above, aircraft catering trucks also have safety interlocks and sensors to prevent accidents due to human error.

One of such features is the Driving Interlock when the stabilizers are engaged i.e. truck’s control system will not allow driver to drive the truck when stabilizers are engaged. This feature will make sure that if the driver mistakenly tries to drive the truck while the stabilizers are active, control system won’t allow it.

Another feature is Stabilizers Retraction Interlock i.e. stabilizers will not retract if the container is in an elevated position. This feature will make sure that if driver mistakenly presses the stabilizers retraction button while its container is elevated, stabilizers don’t retract because it can cause a sudden instability.

Safety Shoe Sensor is a standard safety feature in most aircraft catering trucks. An aircraft’s height does not remain constant when it is on ground. When fuel is added and cargo is loaded, its height reduces due to added weight.

The problem is how would catering truck know if the height of the aircraft has changed from what it was when catering truck was parked? This problem is solved by safety shoe sensor. It senses change in aircraft height and alerts staff if something is wrong.

Safety Shoe Sensor is placed under aircraft door. If aircraft height drops, door presses the safety shoe and safety shoe sends alarm signal to control system.

A proper maintenance program of catering truck fleet of the airline or ground handling company is critical is integral to ensuring ramp safety in catering operation.

Aircraft Catering Truck manufacturing companies are bringing new innovations to catering truck technology to increase safety and efficiency of aircraft catering truck operation.

For example, Mercedes Benz Econic Catering Truck comes with 360 deg. camera coverage that allow the driver to view everything around the truck and eliminate risk of accidents due to blind spot. It also has radar sensors installed on truck sides that alert the driver if it is getting close to any person or any other ground support equipment on the apron.

Similarly, DOLL GSE catering trucks are also a good example of innovative solutions being introduced in aircraft catering truck technology. It has proximity speed control (electronic locking of truck’s speed at minimum when it reaches close to aircraft body); proximity alarms (they alert the driver with an audible alarm when truck is close to any part of the aircraft body); and panoramic cameras to enable the truck driver to have 360 degree view of truck’s surroundings.

Maintenance teams play very important role in ensuring that the safeties and built-in protections work correctly when needed to save operators and catering crew from injury and save the aircraft, catering truck and catering crew from any accident.

Case Study of Aircraft Catering Truck Accident at Changi Airport

Singapore Airlines aircraft Airbus A350-900 was parked at Changi Airport on 09th January 2020 with its catering operation going on after normal parking of the catering truck.

After a while, staff noticed that the catering truck has lowered itself to a level below the aircraft door. It created problem in rolling the meal trolleys between the aircraft and the catering truck.

One of the catering truck operator used the Up Down Toggle switch located in the catering truck front panel to raise the catering truck height back to the level of the aircraft door.

However, it did not work. He went back into the truck’s container to try the same with a second rear cabin switch and asked another staff to tell him when the truck is level.

This time the switch operated and the catering truck platform level started raising. The staff on the other side signaled him to stop raising the truck as the required level had reached and further raising the height would result the catering truck platform colliding with the aircraft door.

The operator inside released the switch but the lifting system did not stop. He immediately pressed the emergency switch, however, catering truck platform had already collided with the aircraft door.

The platform deformed and lifted the aircraft door abnormally. The door hinges could not sustain the pressure applied by the catering truck causing deformation.

The safety shoe also got sandwiched and crushed between the catering truck platform and the aircraft door as it experienced excessive compressive forces applied by the raising platform on one side and a fixed aircraft door on the other.

The accident was investigated by Accident Investigated by Transport Safety Investigation Bureau, Ministry of Transport, Singapore. Investigation found that The truck’s engine idle speed was not the same as manufacturer’s standards at the time of the incident. It was higher.

A higher idle speed of the engine affected the lifting mechanism hydraulics such that the automatic lowering speed of the truck was increased. That was the reason behind truck platform going out of level in the first place.

Secondly, during the lifting operation by operator’s manual command, the safety shoe did not operate otherwise the accident could have been averted. The reason for non-functioning of safety shoe sensor was the algorithm in which the catering truck’s control system worked.

The control system did not consider the signal from safety shoe when manual raising of the platform was being carried out. Due to this reason, while the operators were relying on the safety shoe at the time of the accident, it did not operate because command for raising height was being manually given.

The manufacturer of the catering truck fixed both of the problems and also updated its manuals for future reference. The accident emphasizes the importance of technical and maintenance related functionalities of aircraft catering truck operation.

Safety Precautions During Aircraft Catering Operation

While technology enhances safety, it does not relieve the catering crew from observing safety precautions during the catering operation.

First, Catering truck operator must make sure that chocks have been applied to aircraft wheels. It is important because catering truck is either positioned right in front of the jet engine or behind it with the aft door of the aircraft.

Unexpected movement of the aircraft can result in a collision between the catering truck and the aircraft wing or engine.

The position of aircraft catering truck during its operation is in front and rear of the aircraft jet engine. Therefore, risk of aircraft jet engine ingestion (when catering truck is engaged with the front door); and risk of jet blast (when catering truck is engaged with the aft door) must also be considered.

That is why it is imperative that flight crew knows through proper communication whether catering truck is parked or removed from the aircraft stand.

If wind conditions are extreme, operation of catering truck must be halted. The technical manual of catering truck’s manufacturer must be consulted to check what is the maximum allowable windspeed the truck is designed to sustain.

The outriggers available in the catering truck have a certain capacity to fight winds that may try to unbalance the catering truck. Above its capacity, catering operated must be stopped and catering truck stowed.

Qantas Airways Catering Truck Accident Case Study

On 14th October 2017, Qantas Airways aircraft (Boeing 737) was getting ready for departure and aircraft catering truck operation was about to complete from the aircraft’s rear galley i.e., the door behind the wing of the aircraft.

The dispatch engineer conducted a walk around check of the aircraft to see if all other equipment have been disengaged and safely removed from the aircraft stand.

He stood under aircraft wing to see the completion of catering loading of rear galley. He saw that aircraft door was closed by catering crew which meant that catering was completed. Engineer went to the nose side of the aircraft and established head set communication with flight crew to get ready for pushback operation.

Due to rain, the dispatch engineer had sit inside the pushback tractor right side seat to avoid getting wet. Finally, the Air Traffic Control (ATC) Tower gave okay for aircraft pushback. The dispatch engineer visually checked the ramp by leaning out of the pushback tractor and found the ramp free from any obstruction.

He subsequently gave go ahead to the pushback driver to start the pushback operation and also gave go ahead to flight crew to start the right-side engine. The engine blades started rotating and the pushback began.

Suddenly, the engineer saw that the catering truck had not left the ramp and was in the path of the reversing aircraft’s wing. The engineer yelled at the pushback tractor driver to stop.

The pushback tractor driver applied full brakes to stop the aircraft but the shear pins of the pushback towbar failed and aircraft became disconnected from the pushback tractor.

Flight crew immediately applied the aircraft parking brakes and also cut off the jet engine. However, aircraft rolled backwards by 3-4 meters and collided with the catering truck.

Substantial damage had occurred to the aircraft wing. Fortunately, nobody was injured in the accident.

The accident was investigated by the Australian Transport Safety Bureau. Investigation found the reason behind the accident to be two-fold.

First, the dispatch engineer assumed that catering truck had left the ramp when it hadn’t. This assumption was partly based on his incorrect estimation of the time required for the catering truck to leave the aircraft stand.

The truck had not completely reversed from the aircraft stand when the aircraft pushback began. It was still standing in the patch of the reversing aircraft’s wing.

Secondly, catering truck was not easily visible because of three seasons.

- It was night time and dark.

- It was raining.

- The catering truck view was obstructed from engineer’s angle due to the wing falling in line of the view. By the time engineer saw the catering truck, it was too late to prevent the collision.

The accident emphasizes the importance of checking that all equipment have left the aircraft stand before aircraft pushback begins. Furthermore, catering truck crew must ensure that they leave the aircraft stand as soon as the catering operation is finished.

Meanwhile, catering crew, flight crew and ground engineer must have good coordination to remain updated on the status of catering operation and the catering truck.

So this is it from our side. If you liked our article, please do share it with like minded people in your circle so that our effort reaches at more and more placed where it is helpful.

If you are interested in obtaining a base level knowledge about all the different types of aircraft ground support equipment and operations, Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground support activities and equipment.

Or, if you are interested in obtaining a base level knowledge about ramp safety, check out this 7-hour video based course on Udemy that you can easily finish in a week (or binge watch in a day or two). It explains ramp safety in detail with interesting case studies of ramp accidents for in-depth understanding of the subject. It also explains ramp safety aspects associated with 13 main ground handling operations carried out on the ramp.