Aircraft docking is the first ramp operation and safety during aircraft docking is one of the most important areas of ramp safety.

On 19th December 2013, Singapore airlines flight SQ421 arrived at Changi airport in Singapore from Mumbai, India. During aircraft docking, when the aircraft was rolling on the ramp and was approaching its stop position, an empty cargo container was ingested by the left jet engine of the aircraft causing serious damage to the engine blades, body and internal components rendering the engine unserviceable and resulting in aircraft being grounded until repair.

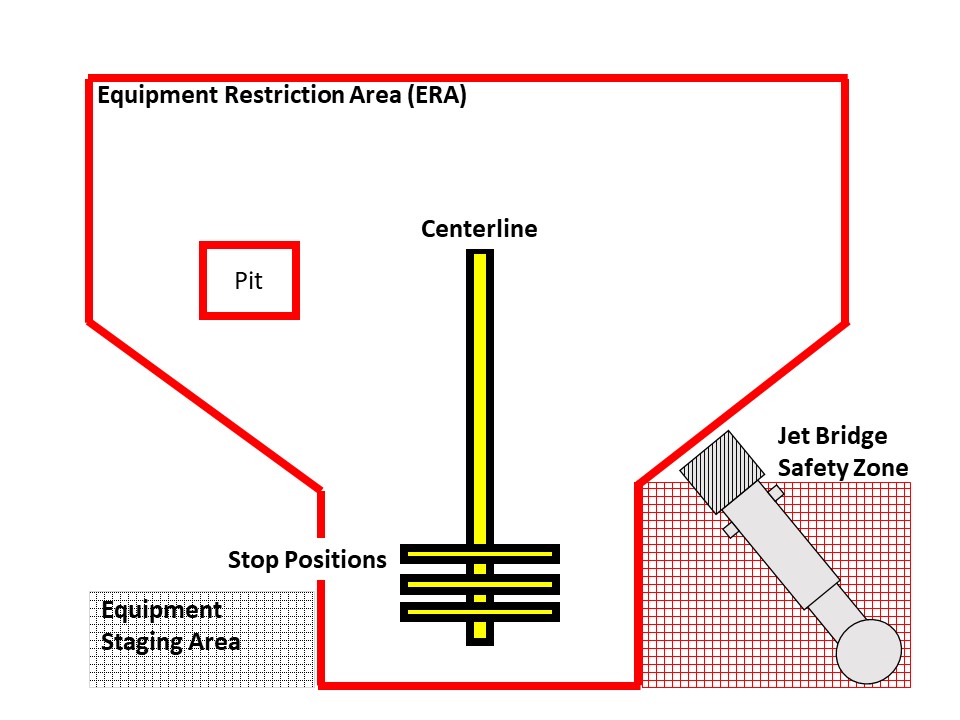

The Air Accident Investigation Bureau of Singapore carried out a thorough investigation of the accident. It found that there was a train of cargo dollies (with containers over them) laying inside the Equipment Restriction Area (ERA) in the ramp during aircraft docking. As the aircraft got near them, the engine sucked one of the empty containers. It went straight into the jet engine coming into direct contact with the rotating fan blades.

What does the above accident teach us?

It shows how an aircraft can run into an accident on the ramp during docking. It teaches us the importance of ramp safety during aircraft docking. This is what today’s article is all about.

Preflight Inspection of Ramp

As soon as Estimated Time of Arrival (ETA) of the flight is passed on to the airport staff, relevant officials carry out a thorough preflight inspection of the ramp. This inspection covers the entire centerline from the aircraft stop bar to the taxilane.

The inspection is generally carried out 15-30 minutes prior to arrival of the aircraft on the ramp (aircraft stand). However, this time can vary depending upon the standard operating procedure developed by the airline, airport or relevant authority.

The above referred inspection covers the following main checks:

- There must be no Foreign Object Debris (FOD) on the ramp.

- There must be no machine, equipment or vehicle in the Equipment Restriction Area (ERA).

- The Jet Bridge must not be outside of its parking zone.

- If Docking Guidance System (DGS) is installed on the aircraft stand, it must be working fine. Otherwise, marshaller must remain available.

These checks are carried out by marshallers, airline technicians or ramp supervisor depending upon the agency made responsible for it. For example, an airline may have leased a certain number of aircraft stands on an airport where preflight inspection of the ramp may be carried out by airline staff itself.

On the other hand, if the airport is involved in provision of airside services itself, it may have its own officials to conduct the inspection and check that everything is okay prior to arrival of the aircraft.

Nonetheless, the important thing to understand is that an authorized official will visit the ramp before aircraft arrival to check that there is nothing abnormal to cause trouble when the aircraft arrives at the ramp.

Safety Aspects in Aircraft Marshalling

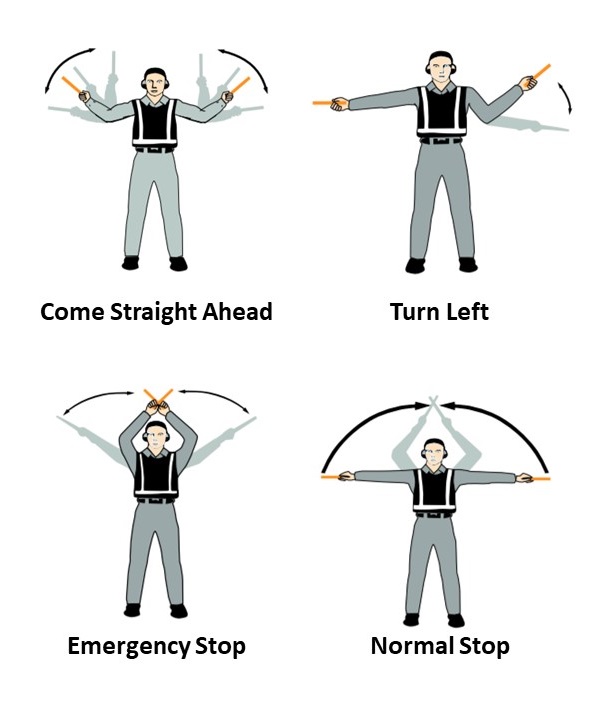

Aircraft marshalling is the activity of guiding the aircraft on the ramp with the help of hand signals establishing a visual communication with the pilot. The official responsible for carrying out marshalling is called a Marshaller.

When the aircraft enters the ramp, the marshaller guides the aircraft to come straight ahead, turn left or right, slow down and stop. The job of the marshaller is very sensitive because he has complete control of guiding the aircraft on the ramp without having any means to talk to the pilot.

Marshaller relies on his hand gestures (or signals) to communicate the pilot how to maneuver the aircraft. This inability to establish audible communication between the pilot and marshaller makes 2 things extremely important for ramp safety:

- Marshaller’s hand gestures are accurate and there is no mistake in the hand gestures.

- Pilot’s interpretation of those hand gestures is correct. There must not be any confusion inside the Pilot’s mind of what the marshaller is trying to say with his hand gestures.

There are thousands of marshallers around the world from different countries and getting training from different institutions. Similarly, there are thousands of pilots from different nationalities trained from different flying schools around the world. How do you make sure that this communication which is dependent on gestures is reliable worldwide?

The answer to above question is Universal Standardization of Marshalling Gestures (or Signals). It is the most important thing in bringing pilots and marshallers on the same page throughout the world. So let’s explain what it is.

Universal Standardization of Marshalling Gestures (or Signals)

The standardized marshalling gestures (or signals) referred above are defined by International Civil Aviation Organization (ICAO). Airports around the world follow the same signaling convention so that there does not remain any chance of confusion between marshallers and pilots that may result in a ramp accident.

The standardization solves the problem of possible misinterpretation. However, at the same time, it calls for a rigorous training program in which marshallers are trained to replicate these signals accurately on the ramp. Similarly, it is made part of pilots training also to understand the gestures (or signals).

Human Factors in Aircraft Marshalling

There are some human factors in aircraft marshalling that are needed to be accounted for in order to ensure ramp safety during aircraft docking.

One important human factor is variance in marshalling gestures. No matter how stringent you are with the training of hand signals of marshallers, there will always be some differences in gestures a pilot observes when he visits different destinations worldwide.

Some marshallers will be taller than others while some will be leaner. These physical differences are just one of the many human factors that will have a personalized effect on the hand signals used in marshalling. Therefore, pilots are trained for paying close attention to marshalling signals in order to avoid any misinterpretation.

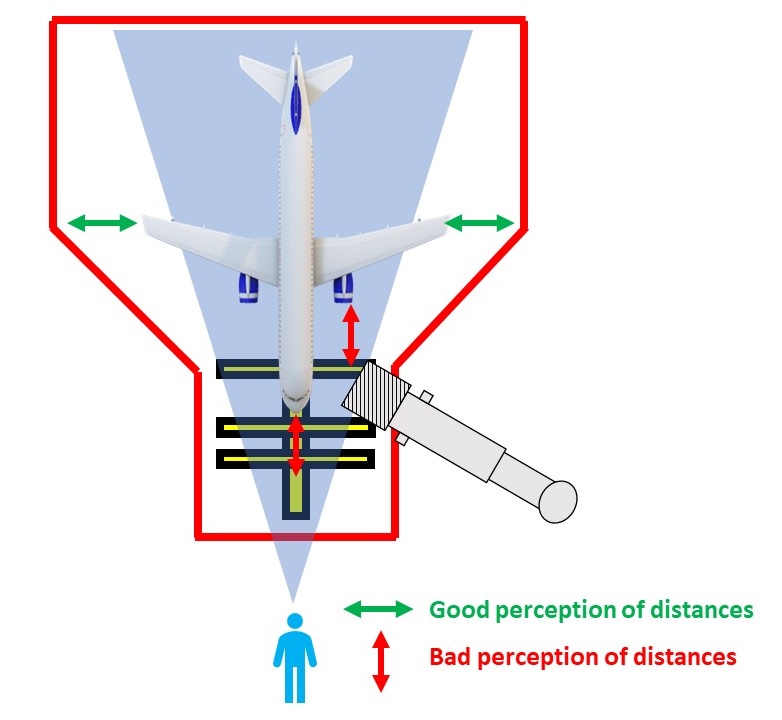

A second important human factor in aircraft marshalling is perspective. Marshallers stand behind the stop position of the arriving aircraft during aircraft marshalling. They have a clear perception of the width of the ramp and the aircraft, however, their perception of the distances along the length of the aircraft are susceptible to error.

While marshallers have a relatively clear perception of the aircraft moving left or right from the centerline on the ramp, they can make a misjudgment in:

- How close is the aircraft nose landing gear to the stop position.

- How far off is the aircraft engine from the jet bridge.

The chances of misjudgment in perspective are reduced through experience. By parking small and large aircrafts day in day out, marshallers develop a feel of how the aircraft moves and how the distances differ. For example, wide body aircrafts can appear to be moving slow even if they are moving at the same speed as a smaller aircraft. Judgment of aircraft speed and position is a must for marshallers for ensuring ramp safety during aircraft marshalling.

How Docking Guidance System (DGS) Improves Ramp Safety

A Docking Guidance System (DGS) is a piece of equipment that automates the work of the marshaller. It has a scanning system and a display system integrated into a single piece of equipment.

The scanning system is generally a laser scanner equipped with cameras and laser range finder devices to scan the aircraft geometry and sense the movement of the aircraft on the ramp. The display system is simply a screen for displaying different instructions and visual cues to the pilot.

The complete unit is installed on a pole located in line with the aircraft centerline of aircraft stand. The unit falls in clear line of sight of pilots sitting inside cockpit of the aircraft. Pilots follow the directions displayed on the screen to park the aircraft.

Over time, Docking Guidance Systems have evolved in technology and latest systems are much more accurate and reliable. Visual Docking Guidance Systems (VDGS) and Advanced Visual Docking Guidance Systems (A-VDGS) are among some common terms used in industry by different manufacturers for the system.

Docking Guidance Systems (DGS) are a solution to human factors involved in aircraft marshalling. The graphical display allows for a much simpler visual communication with the pilot than marshalling signals. It significantly reduces chances of misinterpretation by pilots during the docking maneuver.

Moreover, being an electronic system, it is quicker and more efficient than a human marshaller in transitioning from one command to another during aircraft docking.

For example, if an aircraft is deviating from the centerline on the ramp, a human marshaller is going to guide it back by transitioning from one hand signal to another. This transition from one hand signal to the other has a greater tendency of delay, mistake, misinterpretation or delayed interpretation by the pilot. On the other hand, a Docking Guidance System (DGS) will take virtually no time in transitioning from one command to the other. Moreover its commands are much simpler than hand gestures of a human marshaller thereby reducing chances of delayed interpretation or misinterpretation by the pilots.

Docking Guidance Systems (DGS) also have a bright and luminous display. It is designed to remain visible even under low visibility conditions. This feature improves ramp safety in foggy conditions or rainy conditions where the pilots may not be able to clearly see the hand signals of marshaller.

Another important advantage offered by the Docking Guidance System (DGS) over human marshalling is improving emergency stoppage of the docking aircraft. Marshalling is somewhat communication between two persons only – the marshaller and the pilot. However, DGS makes it possible to include more persons in this communication during emergency.

The emergency button on the DGS control panel (which is generally installed on the ramp) can be pressed by any staff on the ramp to immediately display a stop signal to the pilot. However, in case of a marshaller, the same cannot be accomplished so quickly unless marshaller notices any abnormality himself.

In case some other ramp person notices an abnormality that is not in the view of pilot and marshaller, he will find it difficult to inform the marshaller to exhibit emergency stop hand signals. With the emergency stop functionality of the Docking Guidance System (DGS), emergency stops can be achieved much more quickly.

Owing to the above reasons, Docking Guidance Systems (DGS) improve ramp safety in aircraft docking as compared to aircraft marshalling by human marshallers. Almost all major international airports around the world have Docking Guidance Systems (DGS) installed on all or majority of their aircraft stands.

Advanced Safety Features in DGS

Modern Docking Guidance Systems (DGS) not only scan aircraft geometry but also the vicinity of aircraft centerline. Their scanner has the ability to sense Foreign Object Debris (FOD) and clearly displays it on the display unit so ramp staff and pilots are able to take necessary measures.

Apart from above, they also accurately measure the speed of the aircraft and display the instruction to slow down if the aircraft is rolling on the ramp (or aircraft stand) too fast. Therefore, chances of human error due to any shortcoming in judging speed of the aircraft are reduced.

Modern day Docking Guidance Systems (DGS) also have the ability to communicate with other equipment installed on the ramp to ensure a greater degree of ramp safety. It has electronic interlocks with pit systems (such as a fuel pit) so that if any pit is not properly closed, it displays message on the display unit that pit is open.

Similarly, if the jet bridge is not in its parking zone, the DGS safety interlock with the bridge will activate and display a message on its screen to alert relevant ramp staff that bridge is not in its home position.

Safety Aspects in DGS Operation

When the Docking Guidance System (DGS) is so safe, are any further precautions needed during aircraft docking?

The advantages of Docking Guidance System (DGS) discussed above may have a tendency to make you think that DGS is so safe that no more safety measures are needed once DGS is being used. However, that is not the case.

First and foremost, DGS operators must receive proper training whose curriculum includes teaching full functionality of the equipment, how it is to be used as well as what are the possible confusions that could arise in its use. It must include teaching staff about common errors experienced in DGS and how to fix them.

Secondly, since DGS is an automated piece of equipment, operators and ramp staff have a tendency to lose focus and leave the job at DGS. This must not be done. At least one trained person on the ramp must set his focus on the automated docking in progress on the ramp and intervene if he thinks something is going wrong.

Finally, proper maintenance and calibration of Docking Guidance System (DGS) is necessary for maintaining its reliability and ensuring normal functionality during aircraft docking.

Syrian Arab airlines flight RB447, an international flight from Damascus, Syria arrived at Stockholm, Sweden on 11th December 2006. During docking by a Docking Guidance System (DGS), aircraft wing collided with the jet bridge causing substantial damage to the aircraft and the bridge.

The accident was investigated by Swedish Accident Investigation Board who found multiple reasons to be the cause of the accident. First, wrong aircraft type was fed into the system due to shortcoming in operator training. Secondly, DGS display also had a shortcoming in displaying information regarding different variants of the same aircraft type. Third, the DGS itself did not detect geometrical differences between arriving aircraft and the aircraft fed into it (which were two variants of the same aircraft).

The above accident highlights that having a Docking Guidance System (DGS) on the ramp does not mean that no accident can happen. Ramp safety is improved by a DGS, however, it brings its own safety aspects to be considered for safe operation.

In this way, ramp safety in aircraft docking is addressed both in human marshalling and in the automated docking systems to ensure that no accident or incident takes place on the ramp.

If you are interested in obtaining a base level knowledge about ramp safety, check out this 7-hour video based course on Udemy that you can easily finish in a week (or binge watch in a day or two). It explains ramp safety in detail with interesting case studies of ramp accidents for in-depth understanding of the subject. It also explains ramp safety aspects associated with 13 main ground handling operations carried out on the ramp.