An airplane does not rest. It keeps flying from destination to destination. As soon as an aircraft lands and reaches airport gate, airline staff and ground handling agencies get busy with preparing the aircraft for departure.

Airport ramp operations, ground handling and ground support equipment are terms associated with the set of operations and activities that take place in supporting an aircraft on ground and preparing it for its next flight. We will explore these operations in detail today.

Common Terminologies

Before we look deeper into what airport ramp operations are and how are they undertaken with the help of aircraft ground support equipment, you should be familiar with the terminologies commonly used in industry.

Ground Handling

The term ‘Ground Handling’ refers to the set of activities performed at an airport to facilitate the aircraft that has landed but hasn’t taken off. Hence the name ‘Ground’ handling i.e. handling an aircraft on ground as opposed to flying.

These activities include everything from ramp operations to baggage handling and extends to tasks that fall under airport management.

Ramp & Ramp Operations

When an aircraft lands on the runway, it finally reaches a place commonly referred to as an airport gate where passengers deplane the aircraft. ‘Gate’ is a term that relates more to the interface between an aircraft and airport building i.e. a passenger boarding bridge or lounge gate mentioned on boarding pass of passengers. The area where the aircraft is parked is called an aircraft stand, aircraft bay or ramp.

The term ‘ramp’ has come from maritime industry where the term ‘boat ramp’ has been used for the inclined wooden ramp on seashore used for parking a boat. There is no inclination at an aircraft stand therefore ramp is technically a misnomer, however, it is a term common in industry.

Consequently, all activities involved in servicing an on-ground aircraft and preparing it for departure while the aircraft is parked at the ramp are referred to as ‘ramp operations’ instead of being called aircraft stand operations or aircraft bay operations.

Ground handling is a broad term while ramp operations is a daughter term that covers only on-ramp activities and not off-ramp activities such as baggage loading and unloading on conveyor belts (located away from ramp).

Ground Support Equipment (GSE)

Ground Support Equipment (GSE) refers to specialized machines used for performing different servicing and support activities for the aircraft on ground. These machines are operated by properly trained personnel following standard procedures for carrying out the job with safety.

Airport ramp becomes a very busy place as soon as an aircraft is parked. There is a lot of movement of personnel and GSE all around the aircraft accessing different ground service connections of the aircraft to complete servicing tasks in shortest possible time to make the aircraft ready for the departure.

How Ground Handling Works

Ground handling operations and activities start before the arrival of the aircraft at the airport. The first task in ground handling is assignment of airport gate to an arriving aircraft. It is a decision made by air traffic control of the airport.

Assignment of airport gate is an apron management activity that also comes under the umbrella of airport management as a whole. It includes allocating different gates to different arriving aircrafts after an assessment of already occupied gates and type of arriving aircraft.

As soon as an aircraft lands, air traffic control informs the Pilot of the allocated gate as well as the route to be taken to reach that gate.

Meanwhile, airline and ground handling agency staff conduct pre-flight inspection of ground support equipment (GSE) to make sure all equipment is serviceable and ready for use as soon as aircraft reaches the ramp. All equipment parked elsewhere is towed to the ramp to avoid any delays.

How Ramp Operations Work

Ramp operations begin as soon as the aircraft approaches the ramp. There are more than 10 different ramp operations as given below,

- Aircraft Marshalling for docking the aircraft correctly on the ramp

- Engagement of Aircraft Ground Power Unit (AGPU) for supplying electric power to the aircraft

- Engagement of Jet Bridge (Passenger Boarding Bridge) or Mobile Stairs for deplaning of passengers

- Engagement of Pre-Conditioned Air (PCA) Unit for supplying air conditioning in aircraft cabin

- Baggage loading & unloading with Belt Loaders and Baggage Carts

- Cargo loading and unloading with Cargo Loaders, Cargo Dollies & Unit Load Devices (ULD)

- Replenishment of meals with Aircraft Catering Truck

- Replenishment of potable water with Potable Water Truck

- Refueling with Fuel Hydrant Dispenser or Aircraft Refueler Truck

- Servicing aircraft waste tank with Lavatory Service Equipment

- Deicing and anti-icing of aircraft in extreme winters

- Aircraft engine startup with Air Start Unit (ASU)

- Pushback operation on departure with Aircraft Pushback Tractor

Aircraft Marshalling

When the aircraft approaches the aircraft stand (ramp), another important ground handling activity known as aircraft marshalling is performed. It is the first ramp operation.

Aircraft marshalling refers to guiding the aircraft on the ramp with standardized hand signals by a specially trained ground staff known as aircraft marshaller.

Marshaller signals the pilot to keep coming forward, turn left, turn right and stop. These hand signals are standardized around the world to keep all pilots and ground staff on the same page and ensure that same hand signals convey the same message to the pilot irrespective of the destination.

Why Aircraft Marshalling is Needed?

The need for aircraft marshalling arises because an aircraft cannot be parked anywhere on the ramp and pilots cannot properly park the aircraft on a ramp on their own.

Every ramp has a centerline painted on ground with the aim of keeping the aircraft nose wheel over it to properly orient and center the aircraft on the aircraft stand.

Moreover, there are multiple stop bar positions on the centerline to indicate where different aircraft types will stop on the centerline. It is necessary because different aircrafts have different geometries and are needed to be parked a certain way to ensure safety.

The centerline and stop positions are determined after careful analysis of the airport layout and different aircraft types and sizes planned to be accommodated at different aircraft stands.

These lines ensure safe separation between aircrafts parked on adjacent stands as well as safe separation between aircraft and the jet bridge (passenger boarding bridge). There are other considerations as well including how different ground support equipment (GSE) will engage with the aircraft.

Pilots cannot keep the aircraft nosewheel precisely over the centerline nor stop the aircraft precisely at the designated stop position because they don’t have a clear visual of these markings on ground. Therefore, a marshaller is needed to guide the pilots to correctly park the aircraft.

Visual Docking Guidance System (VDGS)

Aircraft marshalling has been automated at most of the major international airports in the world by a piece of equipment known as Visual Docking Guidance System (VDGS).

It comprises an electronic display installed at the airport gate at the same level as the line of sight of pilots that provides visual cues to the pilot during parking.

The signals are displayed after laser scanners and onboard computer of the VDGS scans the aircraft and makes live calculations about aircraft’s orientation on ground.

Supplying Electric Power with AGPU

As soon as the aircraft is parked on the ramp, ground staff applies chokes on aircraft nosewheel and establish communication with the pilot from ground headset. Once pilot gives go ahead for engagement of ground power, staff connects the Aircraft Ground Power Unit (AGPU) with the aircraft.

After successful connection of ground power is made, pilots turn off the jet engines and aircraft uses ground power to keep the critical onboard systems on.

How Ramp Gets Busy

When jet engines are turned off, multiple ground support equipment invade the ramp and ramp becomes the busiest spot on the airport.

A Jet Bridge (Passenger Boarding Bridge) operator waits for signal from ground crew to begin PBB operation and connects the bridge with the aircraft within 5 minutes of receiving the signal. If Jet Bride is not available, mobile stairs are engaged to deplane the passengers.

Pre-Conditioned Air (PCA) unit is connected for providing fresh conditioned air to keep the atmosphere inside the aircraft comfortable for passengers and crew.

While passengers exit the aircraft, Belt Loaders (on narrow body aircrafts) and Cargo Loaders (on wide body aircrafts) line up with the aircraft cargo compartments to start unloading passenger luggage, cargo consignments and Unit Load Devices (ULD).

Cargo Dollies and Baggage Carts are loaded up and towing tractors are used for transferring all unloaded items to the baggage belts.

After unloading of cargo and baggage of arriving flight is completed, loading of cargo and baggage of departure passengers is started. When cargo and baggage loading is complete, all towing tractors, cargo dollies, baggage carts, belt loaders and cargo loaders are disengaged from the aircraft and driven away from the ramp.

Catering Truck is engaged with the aircraft when aircraft has become empty of passengers and airline staff start replenishment of catering supplies moving back and forth between the truck and galley (onboard kitchen).

Meanwhile, A Potable Water Truck refills the aircraft potable water tank and a Lavatory Service Truck drains the aircraft’s waste tank so that it is ready for the next flight.

Pilots check the fuel level of the aircraft and make a decision about whether or not refueling is required. If it is required, A Fuel Hydrant Dispenser parks itself under or near the wing of the aircraft for refueling.

In case fuel hydrant pits are not available at the airport, an Aircraft Refueler Truck is used for the same purpose.

Each ground support equipment (GSE) is disconnected and removed from the ramp as soon as it finishes its job because keeping the ramp clear of unnecessary machines and vehicles is an important measure for safety and efficiency.

In the end, Jet bridge, ground power unit (AGPU) and Pre-conditioned air (PCA) unit remain engaged until boarding is completed for the next flight. When last passenger boards the airplane and head count is completed, jet bridge is disconnected as well.

At this stage, if a dedicated deicing facility is not available at the airport, deicing and anti-icing of the aircraft may take place at the ramp during extreme winter conditions. Deicing trucks surround the aircraft and spray deicing and anti-icing fluids.

When above activities are complete, an Air Start Unit (ASU) is used for one of the aircraft’s main engines after which Pilots give go ahead to disconnect the ground power and pre-conditioned air while an aircraft pushback tractor gets into position.

After all Ground Support Equipment (GSE) have been disconnected and removed from the ramp, the final ramp operation is the aircraft pushback from the ramp using the Aircraft Pushback Tractor.

Pilot communicates with the control tower and receives go ahead for approaching the runway for takeoff. It marks completion of ground handling and ramp operations.

Other Ground Handling Operations

Ground handling operations are not limited to the ramp. It includes functions performed off the ramp as well including,

- Baggage handling including loading and unloading on conveyor belt system of the airport

- Repositioning of an aircraft from one aircraft stand to another

- Towing an aircraft inside and outside of maintenance hangar

Although services provided at check-in counters, airport lounges and ticketing counters fall under airport services and passenger facilitation, they are often included in ground handling operations.

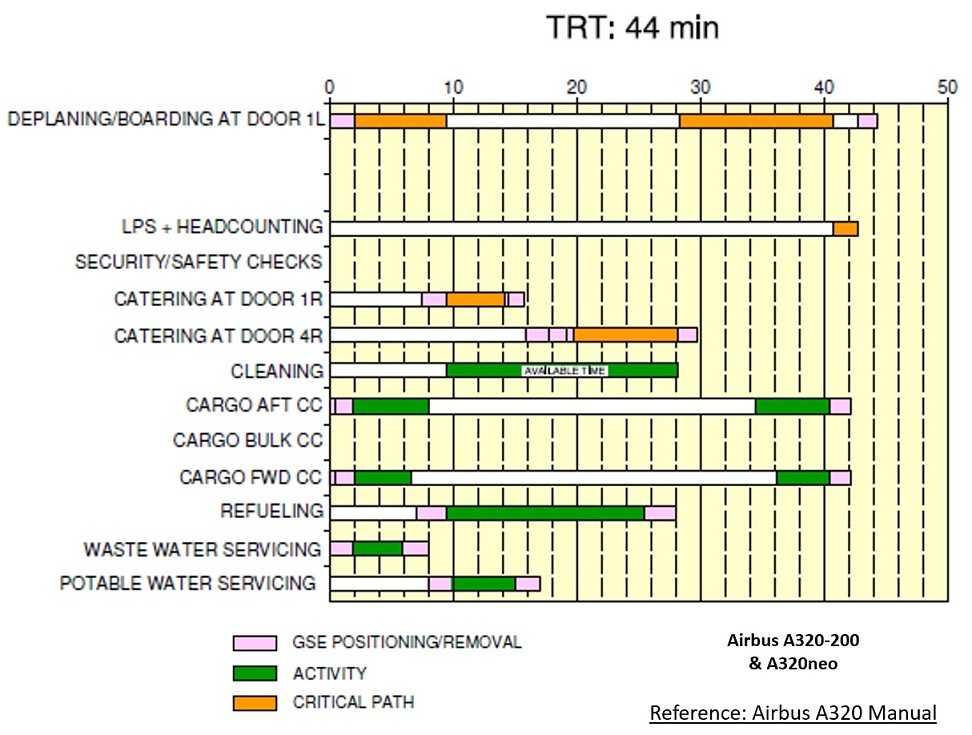

The Concept of Turn Round Time (TRT)

It is important to mention the concept of turn round time (TRT), a term commonly associated with ground handling and ramp operations.

As already described in the start of this article that an aircraft generates revenue flying and not remaining on ground. Aircrafts generally fly from destination to destination without long breaks. Therefore, the time duration in which all servicing activities are completed on an aircraft can become a bottleneck in revenue generation.

On one hand, aircraft manufacturers design aircrafts to make ground servicing as convenient as possible while airlines and ground handling agencies develop ways of completing all activities in such a well-coordinated and efficient manner that reduces the total time an aircraft needs to stay on ground without compromising safety.

This is where the concept of Turn Round Time (TRT) comes in. It refers to the time duration between successful parking of the aircraft and pushback operation i.e. the time duration an aircraft remains on the ramp.

All ground support operations have to be sequenced in a way to minimize idle time of GSE and reduce turn round time (TRT). The sooner the aircraft leaves the ramp for departure the better.

A benchmark turn round time (TRT) is available in aircraft manuals in which the manufacturer provides the optimal time and sequence of ramp operations for the specific type and model of their aircraft.

It serves as a reference for airlines and ground handling agencies to gauge the performance of their ramp services team and identify bottlenecks and areas where improvement is needed.

Turn Round Time (TRT) is optimized by conducting as many ramp operations in parallel as possible safely.

For example, passenger disembarkation can embarkation can take place simultaneously with cargo loading and unloading because jet bridge is engaged on left side of the aircraft while cargo loaders are engaged on the right side. These two ramp operations don’t interfere with each other.

However, some operations cannot be performed in parallel and it is important to sequence them properly.

For example, deplaning and catering replenishment are two ramp operations that cannot be performed simultaneously because replenishment of catering supplies requires movement of airline staff and trollies between aircraft and catering truck that is not possible until all passengers have left the plane.

Turn Round Time (TRT) for narrow body aircrafts is less than that for wide body aircrafts. Moreover, the level of training of ground staff and size of team also play a role in determining how quickly all ramp operations are completed and aircraft is made ready for departure.

So, this was it from our side. If you liked our article, don’t forget to share it with likeminded friends and colleagues.

Want to learn the basics of aircraft ground handling operations and ground support equipment? Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground equipment and associated activities.