Hundreds of cities around the world experience subzero temperatures and face disruption in their normal flight operation due to extreme winter weather conditions. One of the main challenges such weather brings for airports and airlines is the aircraft deicing problem.

In this post, we will discuss why deicing is such a big deal in aviation? What is the scope of this problem? What are aircraft deicing fluids? What is an aircraft deicing truck? What is the difference between Deicing and Anti Icing of an aircraft? and how deicing or anti icing procedure works?

What is Aircraft Deicing?

You might be familiar with the term ‘deicing’ from treatment of highways and roads during extreme winter conditions. Places that experience sub-zero temperatures often face the problem of formation of ice over roads and pavements.

This ice formation is detrimental and dangerous as it creates loss of friction between vehicle tire and road surface thereby compromising its braking action. Consequently, treating highways and roads for removing this ice and prevent traffic accidents becomes necessary.

Government authorities employ contractors for deicing of highways, roads and pavements and you might have seen Government tenders in the newspaper for procurement of deicing agents and chemicals as well as outsourcing of deicing services.

In aviation world, deicing carries a different meaning than the one used in roads and pavements. It refers to treatment of aircraft body to remove ice. In extreme winter conditions, ice is formed over body of aircrafts that is dangerous for flight.

In aviation, deicing refers to the procedure performed at airports for removing ice from the body of an aircraft before it takes off. It is a technical procedure performed by ground handling agencies or airlines themselves through properly trained manpower and involves the use of specialized equipment.

Why Aircraft Deicing is Critical for Flight Safety?

Deicing is a very important topic in aviation because it is directly related with flight safety. If left unaddressed, the risks involved can be put into perspective by revisiting some heartbreaking incidents that aviation world has experienced.

- American Eagle Flight 4184 was flying from Indianapolis to Chicago on 31-Oct-1994. The flight crashed near Chicago airport due to extreme weather conditions in Chicago that caused icing over aircraft’s body and resulted in loss of control. The aircraft went into two full rolls before crashing into a soybean field. None of the 68 people aboard could survive the accident.

- Aero Caribbean Flight 883 was flying from Haiti to Havana, Cuba on 04-Nov-2010. The flight crashed in a village near Havana due to severe winter weather that caused icing over aircraft’s body. There were no survivors.

- China Eastern Airlines Flight 5210 was flying from Mongolia to Shanghai on 21-Nov-2004. The flight crashed just minutes after takeoff due to icing that resulted in complete loss of control. The aircraft had not been deiced before takeoff.

There have been many other accidents throughout aviation history due to ice formation over an aircraft body. Aviation world has learned from these accidents and regulatory bodies have made more and more stringent regulations for aircraft manufacturers as well as airport authorities to deal with the problem.

This is the reason why deicing is critical for flight safety and so much emphasis is laid on its procedures, regulations, checks and balances.

If you have ever talked to aviation professionals on the subject of safety, you might have heard the argument how flying is the safest in all means of transportation as the percentage of people dying due to flight accidents is far less than trains, cars and motorcycles. The statistics so presented are a result of tireless efforts to improve safety standards and regulations surround flight operations.

How Icing on an Aircraft Disturbs its Aerodynamics

When an aircraft lands and reaches airport gate, it remains parked there for a certain time period in which its engines are turned off and different ground support operations are performed including cabin cleaning, catering services and technical checks by aircraft technicians. At this time, aircraft is exposed to ambient conditions of the airport.

Air always holds some amount of moisture in itself. The same moisture condenses and becomes ice over an aircraft that has remained on ground for some time under extreme winter conditions.

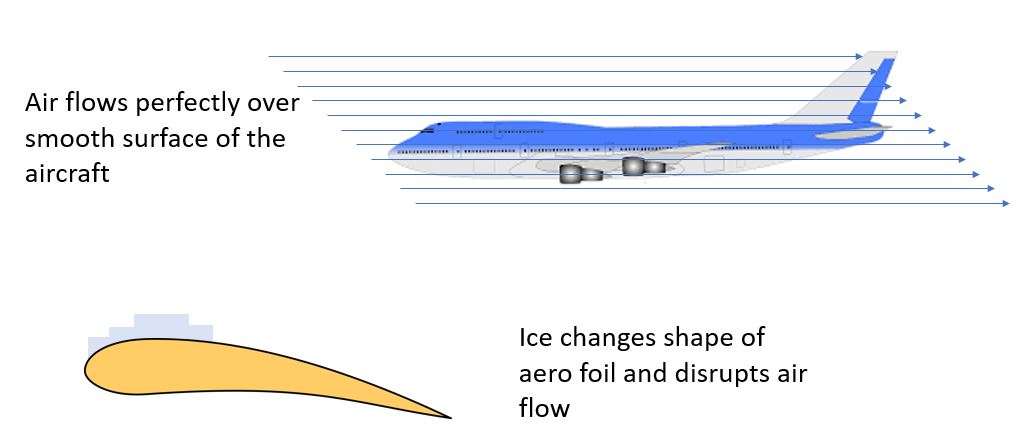

An aircraft is an extremely aerodynamically optimized machine. The shape of aircraft fuselage and wings as well as surface smoothness is engineered to offer minimum resistance to air flowing over its body during flight.

To take it into perspective, cruising speed of airliners easily reaches around 700 kmph. It means that at cruising altitude, air is flowing at a speed of 700 kmph over the body of aircraft. Visualize air flow as a stream of water flowing over a smooth surface and imagine what would happen if you put a pebble there. The flow would disrupt.

When ice forms over the surface of aircraft body or wings, it creates hindrance in the path of air flow and adversely affects aircraft aerodynamics by causing abnormal disruption in the flow of air over aircraft’s body during flight. It causes loss of performance, and under worst case scenario, results in unpredictable flight behavior that has a negative effect on pilot’s control over the aircraft.

Apart from above, icing on ailerons, flaps, slats, spoilers, rudder, elevators and stabilizers, especially on their hinges i.e. line or crevice where they fix with the body is most dangerous because these parts establish control of flight and are most prone to aerodynamic abnormality.

Furthermore, ice can create hindrance in mechanical movement of these parts during flight thereby causing loss of a certain area of control. For example, if hard ice forms over the rudder, pilot may lose control over ‘yaw’ in the aircraft. Similarly, if horizontal stabilizer and elevators are covered with ice, pilot may lose control of ‘trim’ in the aircraft.

Aircraft Deicing Fluid & How It Works

In simple terms, Deicing is simply spraying hot fluid over aircraft body that melts the ice formed over its surface but does not freeze itself (otherwise it would replace ice and freeze itself and kill the purpose of deicing). Once the ice has been removed, aircraft is cleared for takeoff. Let’s look into the science of deicing fluid that holds central importance in the whole activity.

Deicing fluid is very similar to coolants and antifreeze fluids used in automobiles. The concept is that water freezes at 0 deg. C. If you add such a chemical in water that has a much lower freezing temperature or dissolves in a way as to change properties of water, the resulting solution will not freeze at 0 deg. C.

As a result, when ambient temperature gets lower than 0 deg. C, the water inside your radiator will not freeze. This is the basic concept behind antifreeze fluids used in automobiles and the same concept applies in aircraft deicing fluids.

Ethylene Glycol and Propylene Glycol are the common base ingredients used in automobile coolants and antifreeze liquids and the same chemicals are base ingredients in aircraft deicing fluids. The freezing point of ethylene glycol is -12.9 deg. C and the freezing point of propylene glycol is -59 deg. C.

Whenever these chemicals are added to water, antifreeze properties are achieved in the resulting solution. When such a solution is heated and sprayed over an aircraft, its heat will melt the existing ice that will flow off the surface of the body of the aircraft.

However, the deicing fluid will not freeze itself after removing ice because it does not freeze at 0 deg. C.As long as a film of such deicing chemical remains over the body of the aircraft, it will not let moisture take its place while resist freezing itself at the same time. This is the basic scientific principle behind aircraft deicing.

Aircraft Deicing Fluid Types – Difference Between Aircraft Deicing & Anti-icing

Now that we have discussed what deicing is and how deicing fluids work, let us introduce anti-icing fluids and explain how do they differ from deicing fluids.

SAE International, a US based professional association is the leading organization that has developed standards for classifying chemicals used in aviation industry for treating ice formation on aircrafts. The purpose is to bring all manufacturers of these deicing chemicals on the same page.

It is interesting to note than SAE was originally Society of Automotive Engineers that worked in automotive field only. However, it is no more called Society of Automotive Engineers and no more deals in automotive sector. It now deals in development of standards for aerospace and aviation industry.

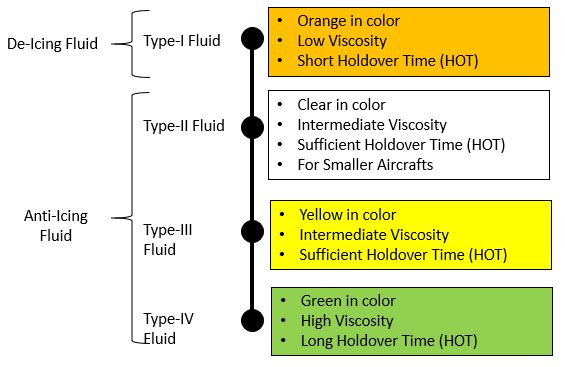

The reason why we are introducing SAE is because the difference between deicing and anti icing is connected with the standards developed by SAE. As per SAE classification, aircraft ice treatment fluids are divided into four main types namely Type-I, Type-II, Type-III and Type-IV fluids with orange, transparent, yellow and green colors differentiating between the type of deicing fluid.

Hold Over Time & Shearing Speed of Aircraft Deicing & Anti-icing Fluids

Although the base ingredient of deicing and anti-icing fluids is common, the difference in fluid properties is created by the concentration of the base ingredient (generally propylene glycol) and other additives especially thickening agents. The difference in deicing and anti-icing fluids springs from two factors, Hold Over Time (HOT) and shearing speed.

Let us first explain Hold Over Time. A fluid sprayed over an aircraft body will stay over the surface for a limited time. Hold Over Time tells us how long the layer of fluid will hold over the surface to prevent icing. Type-II to IV fluids have longer Hold Over Times because they contain thickening agents that increase the viscosity of the fluid. Greater viscosity imparts these fluids the ability to remain over aircraft body for longer. This is how they prevent further icing and are classified as anti icing fluids.

Anti Icing fluids remain over the aircraft surface for a longer time period and prevent ice formation over that time period. It ensures that after the existing ice has been melted and removed, re-formation of ice is prevented.

As for the second factor – shearing speed, Type-II to Type-IV fluids shear off the surface of the aircraft at greater speeds than Type-I fluids. This ability makes sure that the film of fluid remains over the aircraft body when the aircraft accelerates on the runway for takeoff.

Type-I fluids (Deicing fluids) have low viscosity due to which they don’t remain over aircraft body for long. When hot deicing fluid is sprayed over an aircraft, it melts and removes ice from its surface. However, over time, the surface of the aircraft cools down and moisture can condense again thereby forming ice again. Hence the need for anti icing.

Hold Over Time is an additional constraint for pilots, deicing team as well as air traffic controllers because they have to coordinate with each other and plan deicing and anti icing in such a way that the airplane takes off within this Hold Over Time otherwise the whole procedure will have to be repeated.

After anti icing operation has been performed, pilots have a limited time period equal to the Hold Over Time of the fluid in which the airplane has to take off. If due to some reason, airplane does not takeoff in this time period, deicing and anti icing operations may have to be performed again. This is because after expiry of Hold Over Time period, there remains no surety that ice has not formed again over the aircraft surface.

Each type of fluid has color additives to impart them a characteristic color that helps the deicing crew and pilot to easily differentiate between the type of fluid as well as give a visual cue about covering all parts of the aircraft body.

Prerequisites of Aircraft Deicing Procedure

All airports that experience severe winter conditions and the problem of icing have dedicated officials and equipment to perform aircraft deicing operation. Trained operators and staff use a specialized piece of equipment called an Aircraft Deicing Truck to get the job done.

There are certain prerequisites to deicing that are given due consideration before actual deicing procedure is started.

The first is selection of the deicing or anti-icing fluid must be correct. The freezing point of deicing chemical must be lower than the ambient temperature otherwise it kills the purpose of deicing activity. In this regard, deicing fluid to water concentration ratio determines the freezing point of the resulting solution.

The technical team can use refractometer to determine that they have the right concentration ratio giving the desired freezing point to the deicing or anti icing fluid that is lower than ambient temperature conditions.

Once you’ve got the solution right, other factors come into play. In case of rain, strong winds and any other atmospheric factor affecting deicing procedure’s efficacy, flight must wait until such factors are removed.

At night time, there must be sufficient light for the pilot to inspect the icing condition as well as for the deicing team to have a clear view of aircraft parts where spray is being applied.

Apart from above, the aircraft itself has certain preparations for deicing. For example, horizontal stabilizers are adjusted in down position so that deicing fluid easily runs down. Similarly, APU bleed air valve must be in off position to prevent deicing or anti icing fluid fumes from ingestion into the aircraft’s air conditioning system – a potential hazard with respect to inhaling of deicing fluid vapors by passengers sitting in the cabin.

Aircraft Deicing Location – Where is Deicing Performed?

The place where deicing activity takes place also holds significant importance. Deicing can be performed at an aircraft stand, a dedicated deicing facility or a deicing pad (a holding position on taxiway – generally at runway threshold).

Conventionally, aircraft stand is the default location for performing deicing on aircraft. After all passengers have boarded and cargo has been loaded, the passenger boarding bridge is disengaged and all ground support equipment including towing tractors, belt loaders, cargo lifters, hydrant dispenser and catering trucks etc. are removed from the aircraft stand to clear the aircraft for deicing.

At this time, aircraft deicing trucks come in and start deicing or anti icing procedure on the aircraft stand. We will discuss the details of the procedure as well as the working of aircraft deicing truck shortly.

Another place where deicing may be performed is at the threshold of runway on the taxiway. There are two main advantages of carrying out deicing and anti icing on runway threshold. The first is the availability of open space to allow free maneuvering of aircraft deicing trucks. This freedom is restricted on the aircraft stand due to presence of airport building and passenger boarding bridge.

Secondly, deicing the aircraft on runway threshold also helps with regard to Hold Over Time. As already discussed a few paragraphs above that as soon as deicing or anti icing is completed, countdown of Hold Over Time starts and aircraft must takeoff before expiry of Hold Over Time. However, since the aircraft is positioned closest to the runway, there are far less chances of Hold Over Time expiry because as soon as deicing or anti icing is complete, aircraft can enter the runway and take off.

A modern solution to aircraft deicing is construction of a centralized deicing facility at the airport. In this regard, Chicago O’Hare airport is a good example where a dedicated deicing facility has been constructed at an area of over 800,000 sq. ft. that can accommodate up to 20 narrow body aircrafts at a given time.

Toronto Pearson airport is another good example where 180 no. of staff is deployed in a centralized deicing facility that has the capacity to deice 500 aircrafts in a single day.

Such a deicing facility has two main advantages. First, aircraft stand becomes free and available for next flight as the existing aircraft is transferred to the deicing facility. It allows the airport to accommodate greater number of flights and reduces aircraft queues in which aircrafts wait for deicing procedure to finish on the already occupied aircraft stand.

Secondly, a centralized deicing facility improves overall management and efficiency of deicing operations through economies of scale. It makes the overall logistics and deployment of manpower and resources much simpler by confining the activity at a single place as compared to carrying out the process at different aircraft stands.

Time of Performing Aircraft Deicing Procedure

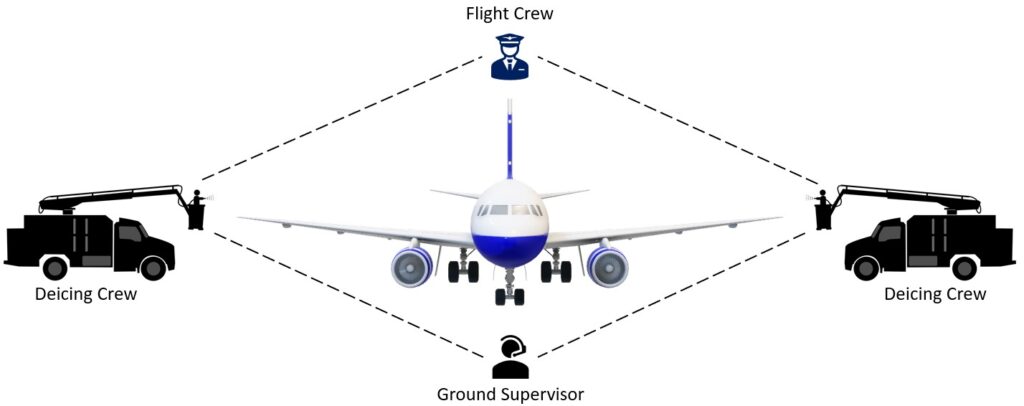

Deicing operation is performed when the airplane is almost ready for departure because the purpose of deicing is to make sure all ice has been removed off the aircraft’s body before takeoff. Pilot conducts an inspection of the aircraft to ascertain the present icing condition on the aircraft. After inspection is completed, deicing crew is given go ahead to start their operation.

The information about the activity is also shared with control tower to make sure clearance for entering runway for takeoff will not be delayed to expire Hold Over Time of deicing or anti icing fluid. Control tower, pilot and the deicing team have to work in harmony for a successful deicing or anti icing activity.

Aircraft Deicing and Anti Icing Procedure

After all prerequisites of deicing have been fulfilled, the actual deicing procedure begins.

One or more deicing trucks position themselves around the aircraft and start spraying deicing fluid over the aircraft body. Deicing fluid is preheated to a specific temperature (60-80 deg. C) and continuous spraying of hot deicing fluid melts and removes ice from the aircraft surface.

However, the hot fluid is not sprayed directly over aircraft windshield, passenger windows, engine intakes, pitot tube sensors and static ports. Ice from these parts is removed manually. Moreover, deicing fluid must not be sprayed over wheels and brakes of the aircraft landing gear. Ice from these parts is removed either manually by hand or with the help of hot compressed air. These considerations are made part of training of deicing crew.

The spraying activity is started and continued until deicing team has satisfied itself through careful inspection that ice has been removed completely from all parts of the aircraft body. After deicing is complete, anti icing is started.

The tricky and the most sensitive areas are the ailerons, flaps, slats, spoilers, rudder, elevators and stabilizers. These parts control the aircraft and if ice prevents their control or disturbs their aerodynamics, it can cause serious problems. Therefore, deicing crew uses manual methods, if found necessary, to remove ice and snow from these parts.

After deicing, crew sprays the anti-icing fluid over the aircraft. It is not necessary for anti icing fluid to be hot at the time of application. The spraying activity is continued until satisfaction of deicing crew is achieved through careful inspection that anti icing fluid has made a film over aircraft body.

A single aircraft deicing truck is sufficient for deicing smaller aircrafts up to Airbus A320. However, larger aircrafts such as the Boeing 777 or 787 require a team of two or more deicing trucks. Either way, aircraft body is completely treated in a systematic way to make sure no surface is missed.

Aircraft Deicing & Anti-icing Equipment – The Deicing Truck

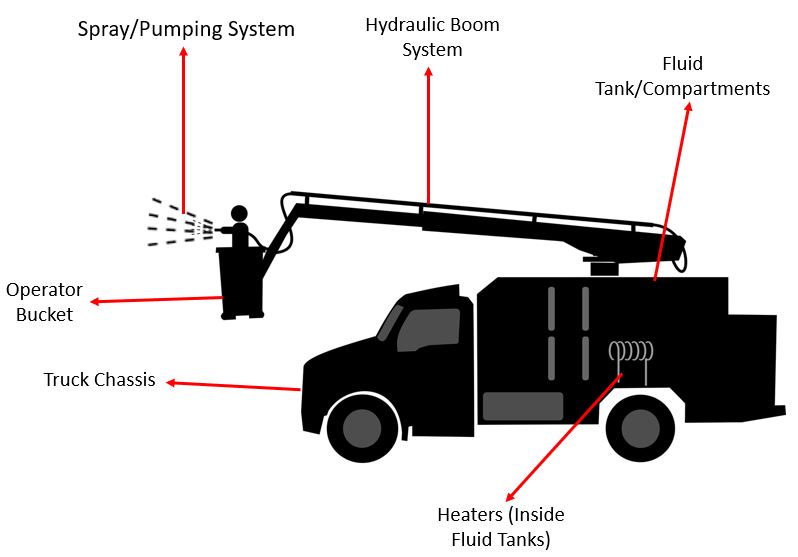

A de-icing truck houses all its systems over a truck chassis that enables it to be driven to the aircraft stand or deicing facility, wherever desired. It has fluid tanks with separate compartments for de-icing and anti-icing fluids.

These compartments are generally made of stainless steel to prevent corrosion. They are also fitted with internal heaters to raise the temperature of fluids to 60-80 deg C before spraying it over the aircraft for ice removal.

The truck is fitted with a hydraulic boom and bucket system to allow the operator to reach different parts and areas at different heights of the aircraft. The boom can extend and retract to bring the operator closer to or away from the aircraft. It can raise and lower itself to adjust height of the bucket. It can rotate about its axes so that a truck positioned at one place does not limit the operator in the bucket from reaching a desired part of the aircraft.

The bucket can either be an open bucket without any weather protection or it can be in the form of a cabin which protects the operator from external weather conditions as well as from the fumes of deicing and anti icing fluids as they are sprayed over the aircraft. These fumes are dangerous for health of operators.

The spraying is carried out by a built-in pumping system powered by the truck’s engine that allows it to spray the fluids over the aircraft with desired pressure and flow rate. The nozzle that ejects the fluid towards the aircraft has the ability to adjust the fluid flow into a narrow jet that penetrates and scrapes off from the surface – generally used during deicing.

The same nozzle can be adjusted to a wide flow than evenly sprays the fluid for forming a layer of fluid over the surface – generally used in anti icing. Moreover, a ground hose and nozzle is also available in the truck that allows spray of fluid under the wing of the aircraft.

A control and measuring system in the form of a user friendly interface is also available in modern deicing trucks that allows live measurement of fluid consumption other important parameters such as fluid temperature and pressure.

An important point to mention here is that deicing needs more pressure than anti icing because the intention is to remove ice formed over the aircraft body. Higher pressure carries more mechanical power to scrape off the ice. Once the ice has been removed, anti icing fluid is sprayed to form a layer or film over the surface of the aircraft to prevent further icing.

An intercom system is also built in the truck to establish communication between the operator standing in the bucket with the driver sitting inside the truck. Moreover, boom and bucket system can be controlled both from the cabin or from the truck. Generally, when deicing is being performed at an aircraft stand, driver takes more control because he needs to maneuver the truck safely around obstacles.

The deicing truck is also fitted with safety systems to prevent accidents. A good example in this regard is the speed interlock that prevents the truck to accelerate past a fixed speed when the boom and bucket are in extended position. It saves the truck from toppling that could occur if the truck driver makes a sharp turn while the boom is in extended position.

Observing Safety During Aircraft Deicing Procedure

A critical safety aspect in aircraft deicing operation is associated with the risk of collision between the aircraft deicing truck, its boom or its bucket and the aircraft body. The risk of collision arises out of the necessity to keep the bucket close to the aircraft body so that the flow and pressure of the spray being carried out from the bucket does not diminish.

To keep the bucket close, the deicing truck itself and the boom also remains close to the aircraft body. While trying to reach a hard spot to spray the deicing or anti-icing fluid over it, there is risk of deicing truck hitting the aircraft with any of its main parts.

Based on above safety risk, it is advisable to keep a third person on ground to just monitor and watch the movement of deicing truck. In case the truck is being maneuvered too close to the aircraft such that a collision can occur, the ground person may immediately intervene and alert the crew.

Delta Airlines Flight 4770 – Aircraft Deicing Accident Case Study

It was an extremely cold winter day on 11th December 2019 when Delta Airlines Flight 4770 was at Portland Jetport in United States ready for departure to New York airport. The aircraft was being deiced prior to take off. While maneuvering the deicing truck and bucket, it hit the tail of the aircraft. Both the deicing truck and the aircraft tail sustained damages.

De-icing procedure was stopped and the aircraft was brought back to the aircraft stand for assessing damages. All passengers were disembarked from the aircraft. Even the lightest of collisions with any part of the aircraft is a serious incident because smallest of imperfections on the aircraft body can cause dramatic aerodynamic abnormalities.

Since, tail of the aircraft was hit in this accident which is one of the main aerodynamic components, therefore there was no question of take off until a safety assessment was conducted. The accident expresses the gravity of the risk of collision between deicing equipment and the aircraft during the deicing or anti-icing procedure.

Importance of Clear Communication Between Deicing Crew & Flight Crew for Safety

The importance of clear communication between all personnel involved in the deicing procedure including the flight crew and the deicing crew cannot be emphasized enough with respect to safety during the deicing or anti-icing procedure.

Both the deicing crew and flight crew must clearly understand, without any ambiguity, the current stage of deicing procedure including

- when aircraft deicing procedure has started;

- when it is ongoing;

- when it has finished; and

- when have the deicing trucks been removed a safe distance away from the aircraft.

Before deicing procedure is started, deicing crew must make sure that pilot has been clearly informed about engagement of the aircraft’s parking brakes until deicing procedure is completed. Otherwise, there is risk of aircraft moving and colliding with the deicing equipment.

Similarly, when the aircraft deicing procedure is completed, the deicing crew must not only inform about the completion of procedure to flight crew but also inform whether or not the deicing equipment has been removed a safe distance away from the aircraft. Otherwise, there is risk of flight crew mistaking completing of deicing procedure with go ahead to move the aircraft.

Although the above mentioned communication may seem trivial, it could both cause and prevent dangerous accidents.

Case Study of Alaska Airlines Ramp Accident During Aircraft Deicing

On 11th March 2017, Alaska Airlines aircraft (a Boeing 737) was pushed back from the aircraft stand on a cold winter evening at Boston International Airport. The aircraft was being deiced before it could depart to the runway for takeoff.

During the deicing procedure, the aircraft suddenly started moving forward while one of the deicing truck’s boom was in the way of the left side aircraft wing. The passengers inside the aircraft also felt the aircraft moving and it is reported they yelled for stopping the airplane. However, it was too late.

The aircraft left wing collided with the boom of one of the deicing truck. Not only did it collide but also caused the deicing truck to tip over under momentum of the aircraft. The operator who was in the deicing truck’s bucket got injured and transferred to a hospital.

The accident occurred because aircraft’s parking brakes were released while deicing was still underway. The accident emphasizes the importance of aircraft parking brakes being set throughout the de-icing procedure. More importantly, it emphasizes the importance of clear communication between pilots and deicing crew at every stage of the deicing procedure.

Case Study of Aircraft Deicing Accident at Munich Airport

On 20th January 2016 at Munich Airport in Germany, Iberia airline Flight with 116 passengers onboard was ready for departure to Madrid airport in Spain. Due to the extreme winter weather, deicing was needed and the aircraft approached the deicing stand.

Flight crew were completing the pre-deicing checks when they experienced a technical problem. Flight crew wanted to abort the deicing operation and just park the aircraft. The same was communicated to the deicing crew team leader to whom the Pilot conveyed that we have experienced a technical problem and we would park to express that we won’t be departing therefore deicing isn’t needed.

The deicing team leader replied that “we will wait”. He didn’t get the intention of the pilot to abort deicing as the plane would not be departing. The deicing trucks kept waiting on the sides for the aircraft to position itself for deicing while the pilot approached the stand with no intention for deicing.

During movement, the aircraft wings collided with deicing trucks positioned on left and right of the aircraft and tilted them by around 20 degrees. The trucks didn’t tip over but the operators were trapped inside. Airport firefighting department was called who rescued the truck drivers out of the deicing trucks.

BFU Germany investigated the incident and attributed the reason to lack of standardized phraseology for deicing operation resulting in misinterpretation of messages between the deicing crew and the flight crew that ultimately resulted in an accident.

The deicing team leader didn’t understand that pilot was aborting deicing due to which deicing trucks remained in position instead of leaving the aircraft. Similarly, pilot did not clearly understand the reply of the deicing team leader when he said “we will wait”.

This is the reason why clarity in communication between the aircraft deicing crew and flight crew is critical for safety.

Recycling & Disposal of Aircraft Deicing & Anti Icing Fluids

Aircraft deicing and anti-icing fluids are not environmentally friendly and there is an ever increasing concern about the potential hazards of these fluids. These fluids can not only harm marine life but also contaminate ground water.

Due to above reasons, more and more emphasis is being laid on procedures for proper disposal of these fluids. Centralized deicing facilities explained above have an advantage in this area as well. These facilities have special drainage system that carry the used deicing and anti icing fluids to a storage point where they can be treated, recycled on properly disposed off.

Once the used fluid is carried to a storage location with the help of specially designed drainage and pumping system, it can either be recycled to be used for deicing or anti icing again – a practice in place at Montreal-Trudeau International Airport that can recycle 2400 liters of deicing fluid per hour, or, it can be sold to companies that can separate propylene glycol from ice, water and dirt and use it for commercial purposes – a practice in place at Pittsburgh International Airport.

How Aircraft Fights Icing During Flight?

While the deicing and anti-icing described above is applicable on ground, an aircraft needs icing prevention systems during flight as well. In flight, the areas most critical with respect to ice formation are the wings and the engine. Ice formation over the wings has the most prominent effect on aircraft aerodynamics whereas ice formation over the engine can have catastrophic outcomes especially if fuel lines get affected.

To deal with icing problem during the flight, majority modern airliners use bleed air. Bleed air is the hot compressed air extracted from compressor stages of the jet engine that is directed to channels made in leading edge of wings and jet engine cowls to keep surface temperatures high enough for ice prevention.

So this was it from our side. We hope we have explained the concept of deicing technically as well as intuitively. If you liked our article, don’t forget to share it with people sharing the same interest as us and you.

If you are interested in obtaining a base level knowledge about all the different types of aircraft ground support equipment and operations, Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground support activities and equipment.

Or if you are interested in obtaining a base level knowledge about ramp safety, check out this 7-hour video based course on Udemy that you can easily finish in a week (or binge watch in a day or two). It explains ramp safety in detail with interesting case studies of ramp accidents for in-depth understanding of the subject. It also explains ramp safety aspects associated with 13 main ground handling operations carried out on the ramp.