Airliners carry tonnes of passenger luggage and cargo consignments in their cargo compartments that is needed to be loaded and unloaded in a short period of time. The real challenge in loading and unloading of cargo in an aircraft lies in the time constraint.

An aircraft earns revenue when it is in the air therefore airlines don’t want it to remain on ground. As soon as an aircraft lands, preparations for the next flight are started.

These preparations include unloading all baggage and cargo of arrival flight and loading new cargo of departure flight. Specialized machines and well coordinated teamwork ensure that this task does not delay the departure of the aircraft.

In this post, we will look at how baggage and cargo loading and unloading works at an airport with an emphasis on understanding the ground support equipment involved in the process.

Baggage Journey from Airport Lounge to Aircraft Stand

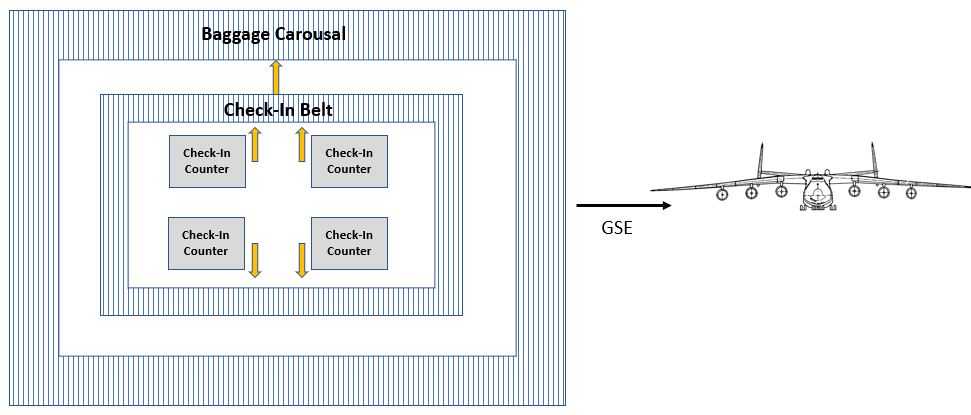

An airport has a complex system of conveyor belts that receives passenger luggage from check-in counters located in airport lounges and transports it to different parts of the airport.

The whole network of conveyor belts can be several kilometres long on a large airport. It all starts when you check in your baggage at the check-in counter of the airport departure lounge.

Check-in counter staff loads your baggage to check-in belts that transfer the baggage to a series of conveyor belts that ultimately carry the baggage to a baggage carousal where airline staff is deployed for further action. At this stage, baggage is still in airport building.

Airline staff transfers all the baggage manually from the baggage carousal to a baggage cart or a Unit Load Device (ULD) that we will explain later in this post. For now, let’s stick with baggage cart.

Ground handling staff loads up multiple baggage carts and hooks them with each other to make a train of baggage carts to be towed to the aircraft. At this point, baggage is ready to leave the confines of airport building.

A towing tractor is used for towing the train of baggage carts from airport building to airside on the aircraft stand or bay where the aircraft is parked.

Multiple rounds of the towing tractor are required for carrying complete baggage for a large airliner like a Boeing 777 or 747. At this point, baggage is at the aircraft bay under open air, outside the confines of airport building and ready to be loaded to the aircraft cargo compartment.

Belt Loaders

Once baggage carts are received at the aircraft stand, it is time to load the baggage to aircraft cargo compartment. The problem is that aircraft cargo compartment door is located several feet high from the ground therefore baggage cannot be loaded manually inside it.

There is a specialized ground support equipment called a Belt Loader that is used for doing the job.

A belt loader is simply a mobile conveyor belt. It has a conveyor belt installed on a boom whose inclination can be adjusted to match the height of aircraft cargo compartment.

Conveyor belt is powered by a motor that can rotate in both directions to allow both loading and unloading. The end of the boom has a rubber bumper to prevent any scratches or indentation on aircraft fuselage due to contact between the belt loader and aircraft body. The whole system is installed over a truck chassis for mobility.

How the procedure works is simple. Forward direction button on cargo loader control panel is pressed for loading that turns on the belt loader conveyor belt.

One or two team members unload baggage from baggage carts and load it on belt loader manually. Baggage travels up the inclination and does not slide down due to friction between baggage and conveyor belt fabric.

An operator already waiting inside the aircraft cargo compartment receives the baggage and organizes it inside the compartment. In this way, man and machine work together for loading baggage inside cargo compartment.

Unit Load Device (ULD) & Cargo Dolly

An alternate of using baggage carts is a Unit Load Device (ULD). It is a standardized container for storing aircraft baggage or cargo. ULD dimensions and sizes are standard where a specific ULD type is suited for specific aircraft types.

The dimensions and sizing is based on the design of cargo compartments of the aircraft types the ULD is compatible with.

International Air Transport Association (IATA) regulates ULDs to make the overall management of ULDs more streamlined. Each ULD has a unique code that conveys the type of ULD, its serial number and information about its owner (generally an airline).

The main advantage of using a ULD is time saving. Baggage is bundled together into fewer handling units that are easier and quicker to load and unload.

Moreover, organizing baggage inside cargo compartments also becomes less laborious because manual sorting is not required. A ULD is designed to slide and fit inside cargo compartment with provisions to properly secure it to the surface and prevent movement or dislocation during flight.

Unit Load Devices (ULDs) are used not only for baggage but for other cargo consignments as well such as mail and spare part packages.

How Unit Load Devices (ULD) make baggage and cargo handling simple is not difficult to understand. Instead of unloading baggage from airport baggage carousal to the baggage cart, staff loads baggage inside ULDs.

These ULDs are placed over Cargo Dollies that are special carts made for loading ULDs and transferring them to aircraft bay by using towing tractor just like in baggage carts.

A Cargo dolly has a specialized engineering design for holding ULDs. It has rollers that prevent scratches over ULD when staff push and pull it over the cargo dolly. Moreover, it has built in locks to grip the ends of ULDs to prevent them from sliding over the cargo dolly and possibly falling down when towing tractor is towing them and making turns.

Cargo Loader

Once ULDs have been transported to aircraft stand with the help of towing tractor, ULDs are loaded inside aircraft cargo compartment by a special machine called a cargo loader because belt loaders are not designed to load ULDs.

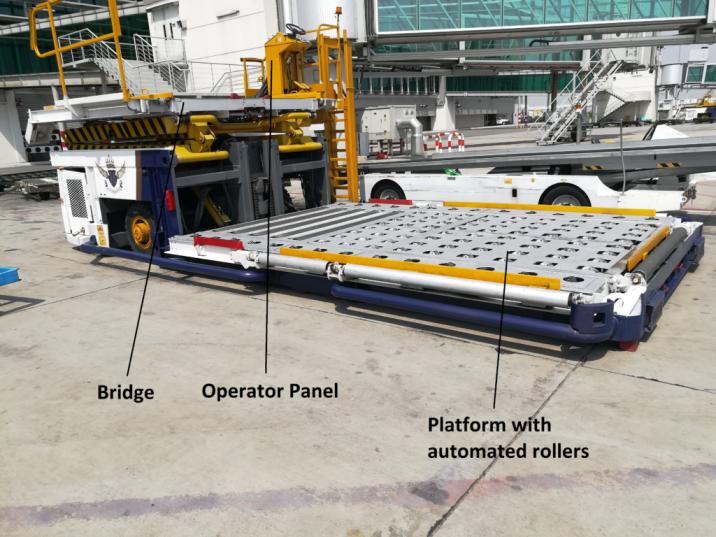

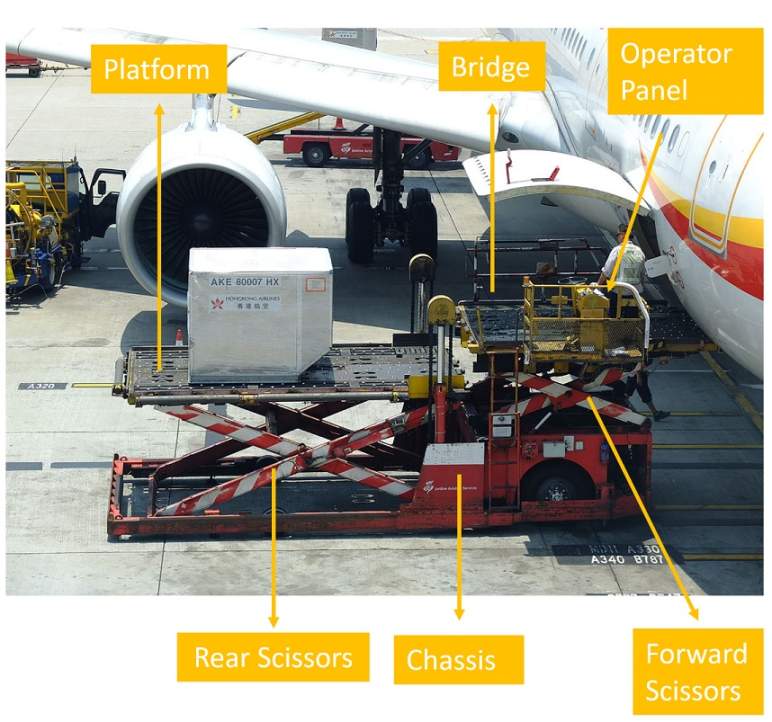

Like many other ground support equipment, a cargo loader has the whole system built over a truck chassis that can be driven to the desired aircraft stand for operation.

It has two platforms. The platform on the front is called bridge because it acts as bridge between the aircraft cargo compartment and loading platform. Bridge is installed over a scissor lift so that its height could be adjusted with the height of the aircraft door.

Operator panel is also located over the bridge that controls the elevation movements as well as drives the truck.

The loading platform is where the ground crew loads all the ULDs from cargo dollies. It is also mounted over a scissor lift mechanism that can raise it or lower it independent of the bridge.

After ground crew loads ULDs over the platform, operator raises the platform to the same height as the bridge which is at the same height as aircraft door. It brings all three levels at the same height and sets the system up for transferring ULDs and cargo packages inside aircraft’s cargo compartment.

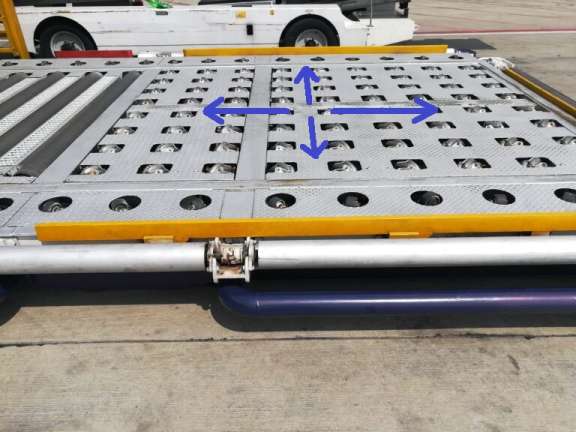

The platform of cargo loader is fitted with special automated rollers that move the ULDs from the platform to the bridge to the cargo compartment automatically.

These motorized rollers transform the loading platform into a grid over which a ULD can move in two dimensions without human intervention. It can rotate ULD over its axis, move ULD forward, backward and sideways to give operator the freedom to transfer the ULD to cargo compartment without any human support.

Manufacturers make cargo loaders of different capacities (in terms of payload) and different service heights based on the types of aircraft they are designed to service.

A Look Inside Aircraft Cargo Compartment

The cargo compartment of an aircraft is like a combination of locking mechanism of cargo dollies and rolling mechanism of cargo loader platform spread over a large area.

Staff does not need to manually arrange ULDs inside the aircraft cargo compartment. All that is needed is to control the automated grid of rollers that will take the ULD to its desired spot inside the compartment without much human interference.

Once the ULD has reached its spot, a locking mechanism locks it in place to prevent it from sliding around and possibly getting damaged during aircraft takeoff, landing and other maneuvers in the air.

Cargo & Baggage Handling in Arrival & Connecting Flights

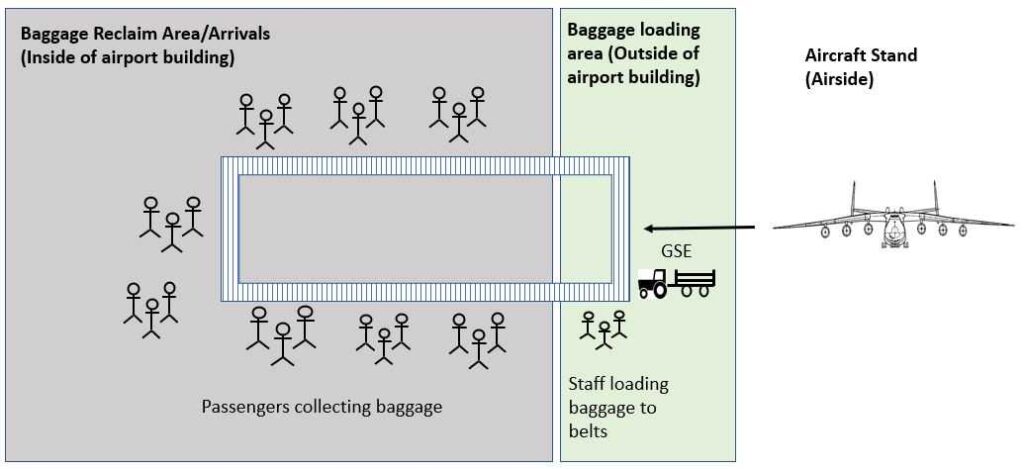

For unloading of Cargo and Baggage, the whole procedure is reversed. Cargo loaders unload cargo; belt loaders unload baggage; staff loads up baggage carts or ULDs over cargo dollies on the apron from where they are towed to the airport building.

Cargo dollies having ULDs mounted over them and baggage carts having baggage loaded over them from the aircraft are taken to the airport building where staff unloads baggage over baggage reclaim belts from where passengers collect their luggage.

Similarly, in connecting flights, instead of transferring baggage and cargo to the airport, it is transferred to another aircraft. This is the reason why time is of paramount importance in cargo and baggage handling. Any delay directly affects flight schedule and results in undesirable complaints from passengers.

With this we conclude today’s post and hope that we have explained all details of cargo and baggage handing at an airport. If you have any suggestions, do let us know and share our article with people sharing the same interest as you and us.

If you are interested in obtaining a base level knowledge about all the different types of aircraft ground support equipment and operations, Check out this 3 Hour video based course on Udemy that explains each of nearly 20 different aircraft ground support activities and equipment.